Motorized emptying and transport refers to a vehicle equipped with a motorized pump and a storage tank for emptying and transporting faecal sludge septage and urine. Humans are required to operate the pump and manoeuvre the hose, but sludge is not manually lifted or transported (see also human powered and transport) . Motorised emptying and transport, is fast and generally efficient. Moreover, it can generate local jobs. But large streets are required for the trucks to pass, thick or dried material cannot be pumped and garbage in pits may block the hose. Moreover capital costs are high and spare parts may be not available locally.

| In | Out |

|---|---|

Faecal Sludge, Faeces, Excreta, Organic Solid Waste |

In the absence of a sewer system and where toilet products can not be reused on-site, faecal sludge from pit latrines, septic tanks, biogas settlers and other water-reliant on-site sanitation systems need to be emptied regularly. This can be done either human powered or by a truck.

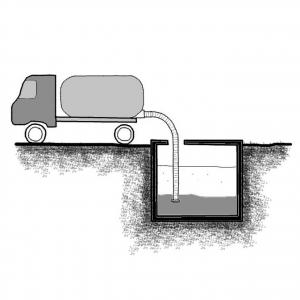

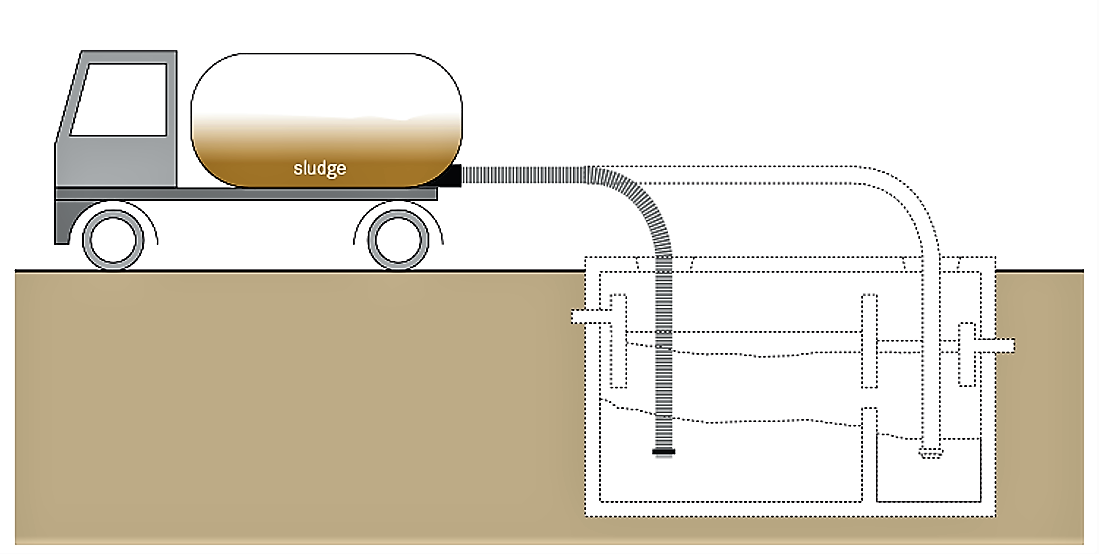

A truck is fitted with a pump which is connected to a hose that is lowered down into a tank (e.g., Septic Tank) or pit, and the sludge is pumped up into the holding tank on the vehicle. This type of design is often referred to as a vacuum truck. Generally, the storage capacity of a vacuum truck ranges between 3 and 12m3 (TILLEY et al. 2014).

Depending on the toilet system, the material to be pumped out can sometimes become very compacted that it cannot easily be removed (TILLEY et al. 2008). In these situations, the solids have to be liquefied with water in order to flow more easily (TILLEY et al. 2008). If water is not available, the waste will have to be removed manually. Faecal sludge collection and haulage are particularly challenging in metropolitan centres with their often large and very densely built-up, low-income districts. Large trucks often have difficulty accessing the latrines or septic tanks in areas with narrow or inaccessible roads (EAWAG/SANDEC, 2008). If there is no access for trucks, other techniques such as human powered pump and vehicle will have to be used. Alternative motorized vehicles or machines have been developed for densely populated areas with limited access. Designs such as the Vacutug, Dung Beetle, Molsta or Kedoteng carry a small sludge tank and a pump and can negotiate narrow pathways.

All vacuum tanker systems use a pump to create a vacuum in the tank and suction hose. The vacuum then lifts the sludge into the tanker. If the bottom layers of sludge are compacted, they can be broken up with a long spade, or jetted with a water hose, before being pumped out. Water hoses (with their own water tanks) are often fitted to the tankers. Some tankers have high-powered vacuum pumps and an air stream into the suction hose that acts as a transport medium for the sludge (“air drag” or “plug and drag” techniques; BRIKKE & BREDERO 2003). These tankers can deal with heavy sludge in pit latrines (especially at the bottom where solids have settled out and organic material has broken down). A small amount of sludge should always be left in the pit to ensure that decomposition continues rapidly (see also septic tanks). Vacuum tankers can be emptied by pressure discharge or by tipping the tank (BRIKKE & BREDERO 2003).

The vacuum truck service and its O&M are usually organised and executed by a professional organisation, normally under the responsibility of the municipality. User fees for the service are usually set officially (and often heavily subsidised), either by the organisation or the government. There is very little involvement of the households being served. Management and supervision of the services are often ineffective. In many areas, for example, the lack of vacuum tankers results in poor service (BRIKKE & BREDERO 2003).

Generally, the storage capacity of a vacuum truck is between 3 and 12 m3. Local trucks are commonly adapted for sludge transport by equipping them with holding tanks and vacuums. Modified pick-ups and tractor trailers can transport around 1.5 m3, but capacities vary. Smaller vehicles for densely populated areas have capacities of 500 to 800 L. These vehicles use, for example, two-wheel tractor or motorcycle based drives and can reach speeds of up to 12 km/h. Pumps can usually only suck down to a depth of 2 to 3 m (depending on the strength of the pump) and must be located within 30 m of the pit. In general, the closer the vacuum pump can be to the pit, the easier it is to empty.

One of those vehicles to empty pit latrines and septic tanks in areas of difficult access is the Vacutug. The UN-HABITAT Vacutug Project was conceived in 1995 with the goal of developing “fully sustainable system for emptying pit latrines in unplanned, peri-urban areas and refugee camps in the developing countries” (see also UN-HABITAT n.y.). The Vacutug consists of a 0.5 m³ steel vacuum tank connected to vacuum pump which is connected to a gasoline engine. On level ground, the vehicle is capable of around 5 km/h. The waste sludge can be discharged under gravity or by slight pressurisation from the pump (TILLEY et al. 2008).

Another possibility is to combine small and large equipment. In this way nearly 100% of the houses can be covered. The pit latrines or septic tanks are emptied by a Vacutug and collected in a storage tank, which can be hook-lifted and hauled away by a vacuum truck (STRAUSS et al. 2002).

The use of a vacuum truck presents a significant health improvement over manual emptying which is quite unsafe and unhygienic and helps to maintain the Collection and Storage technology. Still, truck operators are not always accepted by the community and may face difficulties with finding appropriate locations to dump and transfer the collected sludge.

Another problem could be the discharge of collected faecal sludge. Managing the faecal sludges collected from on-site sanitation systems is a crucial element in public health protection and key to successful water and sanitation projects, especially since one vacuum truck dumping sludge indiscriminately is equivalent to the open defecation of 5000 people (KONE et al. 2007).

Most pump trucks are manufactured in North America or Europe. As such, it is difficult to locate spare truck parts and a local mechanic to repair broken pumps and trucks. New trucks are difficult to obtain, very expensive and thus rarely purchased. Local trucks are commonly adapted to serve as vacuum trucks by equipping them with holding tanks and vacuums (TILLEY et al. 2008).

Maintenance accounts for at least one quarter of the costs incurred by the operator of a vacuum truck. Fuel and oil account for another quarter of the total operating costs. Owners/operators must be conscientious to save money for the purchase of expensive replacement parts, tires and equipment. The replacement could be essential to the working of the vacuum truck (TILLEY et al. 2008).

Initial costs of a vacuum truck can vary enormously and depend on the manufacturer, the condition of the equipment, the country of use, etc. Prices can vary from US$ 20 000–100 000 or more (BRIKKE and BREDERO 2003).

However, the small Vacutug is more economical. Recent results indicate that under certain circumstances (constant number of pits, transfer station, short transfer distance, etc.) the Vacutug can be sustainable and cover its operating and maintenance costs (TILLEY et al. 2008).

Most pump trucks are manufactured in North America, Asia or Europe. Thus, in some regions it is difficult to locate spare parts and a mechanic to repair broken pumps or trucks. New trucks are very expensive and sometimes difficult to obtain. Therefore, older trucks are often used, but the savings are offset by the resulting high maintenance and fuel costs that can account for more than two thirds of the total costs incurred by a truck operator. Truck owners must be conscientious to save money for the purchase of expensive replacement parts, tires and equipment. The lack of preventive maintenance is often the cause for major repairs. The most important checks, especially for vacuum trucks, are listed below (adapted from BRIKKE and BREDERO 2003):

Daily Checks before Work

- the oil levels in the vacuum pump, oil-cooling tank, hydraulic tank and tanker engine

- the tanker fuel level

- the water levels in the tanker engine, the windscreen water bottle, the wash tank, and the water tank for the vacuum pump

- are all the necessary materials present

- the cooling radiator for the hydraulic oil and pump oil

- is the rear door closed and secured

Daily Operation after Work

- drain the sludge and oil separators

Weekly Checks

- tyre pressures, lights, indicators, horns

- valves that prevent the tank from being overfilled

- contacts between gaskets and seats, and performance steel balls;

- leaks in the hydraulic system (tighten couplings), and power take-off shafts (depending on type)

The addition of chemical additives for desludging is not recommended because they tend to corrode the sludge tank.

| Working Principle | The pump is connected to a hose, which is lowered down into a septic tank or pit, and the sludge is pumped up into the tank mounted on a truck or a small vehicle in the case of a Vacutug. |

| Capacity/Adequacy | Vacuum trucks: urban or peri-urban areas with roads (conventional system), or with reasonable access (for mini tankers). Vacutugs: in unplanned peri-urban areas and refugee camps where the access for trucks is impossible. |

| Performance | It is a fast and clean method to empty pits and septic tanks. The workers and the public are protected and do not have direct contact with faecal sludge |

| Costs | Vacuum trucks are very expensive. Vacutugs are more economical, but maintenance costs must be considered in both systems. |

| Self-help Compatibility | The mechanised systems need to be operated by skilled workers. Spare parts might be difficult to find. Therefore the maintenance is very important. |

| O&M | Expensive and maybe complex |

| Reliability | If well maintained and constructed it is usable for many years. |

| Main strength | No direct contact with the faecal sludge, fast and clean emptying of pits and septic tanks |

| Main weakness | Costs are high and the illegal/improper discharge of the collected sludge could raise public health and environmental problems. |

Depending on the Collection and Storage technology, the sludge can be so dense that it cannot be easily pumped. In these situations it is necessary to thin the solids with water so that they flow more easily, but this may be inefficient and costly. Garbage and sand make emptying much more difficult and clog the pipe or pump. Multiple truckloads may be required for large septic tanks.

Although large vacuum trucks cannot access areas with narrow or non-driveable roads, they remain the norm for municipalities and sanitation authorities. These trucks can rarely make trips to remote areas (e.g., in the periphery of a city) since the income generated may not offset the cost of fuel and time. Therefore, the treatment site must be within reach from the serviced areas.

Transfer Stations and adequate treatment are also crucial for service providers using small-scale motorized equipment. Field experiences have shown that the existing designs for dense urban areas are limited in terms of their emptying effectiveness and travel speed, and their ability to negotiate slopes, poor roads and very narrow lanes. Moreover, demand and market constraints have prevented them from becoming commercially viable. Under favourable circumstances, small vehicles like the Vacutug are able to recover the operating and maintenance costs. However, the capital costs are still too high to sustainably run a profitable business.

Both the sanitation authority and private entrepreneurs may operate vacuum trucks, although the price and level of service may vary significantly. Private operators may charge less than public ones, but may only afford to do so if they do not discharge the sludge at a certified facility. Private and municipal service providers should work together to cover the whole faecal sludge management chain.

Emptying on-Site Excreta Disposal Systems. Field Tests with Mechanized Equipment in Gaborone (Botswana)

This report describes field tests of three prototype pit latrine emptying systems, a hand operated diaphgram pump and two vacuum tankers in regular service in Africa. Numerous sludge samples were taken and their viscosities and compositions measured to establish limits for the types of sludges that can be removed by each system.

BOESCH, A. SCHERTENLEIB, R. (1985): Emptying on-Site Excreta Disposal Systems. Field Tests with Mechanized Equipment in Gaborone (Botswana). (= IRCWD-Report 03/85 ). Duebendorf: International Reference Centre for Waste Disposal URL [Accessed: 22.07.2014]Linking Technology Choice with Operation and Maintenance in the context of community water supply and sanitation. A reference Document for Planners and Project Staff

This document is addressed to planners and staff of water supply and sanitation projects on household and community level. The reader is guided through the main steps of informed choices regarding the main proven technologies for water supply, purification and water treatment at household and community level. Each technology is described in a small factsheet, regarding its functioning, actors and their roles, the main operation and maintenance (O&M) requirements and problems, which can occur.

BRIKKE, F. BREDERO, M. (2003): Linking Technology Choice with Operation and Maintenance in the context of community water supply and sanitation. A reference Document for Planners and Project Staff. Geneva: World Health Organization and IRC Water and Sanitation Centre URL [Accessed: 03.06.2018] PDFBusiness Analysis of Fecal Sludge Management: Emptying and Transportation Services in Africa and Asia

This study maps the urban sanitation situation and assesses business and operating models for fecal sludge management in 30 cities across 10 countries in Africa and Asia, specifically focussing on the extraction and transportation market segments.

CHOWDHRY, S. KONE, D. (2012): Business Analysis of Fecal Sludge Management: Emptying and Transportation Services in Africa and Asia. Seattle: Bill & Melinda Gates Foundation URL [Accessed: 22.07.2014]Faecal Sludge Management. Lecture Notes

This module pays special attention to the haulage, treatment and reuse or disposal of faecal sludge. It covers both technical and non-technical (socio-cultural, economic, political etc.) aspects and provides practical information on design, financing and planning of faecal sludge treatment plants.

EAWAG/SANDEC (2008): Faecal Sludge Management. Lecture Notes. (= Sandec Training Tool 1.0, Module 5 ). Duebendorf: Swiss Federal Institute of Aquatic Science (EAWAG), Department of Water and Sanitation in Developing Countries (SANDEC) URL [Accessed: 23.05.2012]Towards an Improved Faecal Sludge Management (FSM)

More than two billion urban dwellers in developing countries use on-site sanitation facilities such as pit latrines, septic tanks and aqua privies for excreta and wastewater disposal. Since on-site sanitation installations will serve the growing urban populations in developing countries for decades to come, increasing faecal sludge quantities will have to be managed. Proper faecal sludge management (FSM) is the important link missing in integrated urban sanitation upgrading efforts.

KONE, D. STRAUSS, M. SAYWELL, D. (2007): Towards an Improved Faecal Sludge Management (FSM). Duebendorf: EAWAG/SANDEC URL [Accessed: 15.12.2010]Investigation into Methods of Pit Latrine Emptying

Many developing countries have embarked on the construction of pit latrines and improved sanitation in people’s homes. An emerging challenge that is resulting from this work is what to do when the latrines are full. If they are to be emptied how should the waste be extracted, where should the waste go and what should be done to it and with it? The approaches to meeting this question are the focus of this report.

O’RIORDAN, M. (2009): Investigation into Methods of Pit Latrine Emptying. Management of Sludge Accumulation in VIP Latrines. (= WRC Project 1745 ). Pretoria: Water Research Commission URL [Accessed: 22.07.2014]Faecal Sludge Management

This is the first book to compile the current state of knowledge on faecal sludge management. It addresses the organization of the entire faecal sludge management service chain, from the collection and transport of sludge, to the current state of knowledge of treatment options, and the final end use or disposal of treated sludge. It presents an integrated approach that brings together technology, management, and planning, based on Sandec’s 20 years of experience in the field. It also discusses important factors to consider when evaluating and upscaling new treatment technology options. The book is designed for undergraduate and graduate students, engineers, and practitioners in the field who have some basic knowledge of environmental and/or wastewater engineering.

STRANDE, L. ; RONTELTAP, M. ; BRDJANOVIC, D. (2014): Faecal Sludge Management. Systems Approach for Implementation and Operation. London: IWA Publishing URL [Accessed: 16.07.2014]FS Management – Review of Practices, Problems and Initiatives

A study on management and institutional aspects regarding the challenges and possible improvements in managing faecal sludge.

STRAUSS, M. MONTANGERO, A. (2002): FS Management – Review of Practices, Problems and Initiatives. London and Duebendorf: DFID Project R8056, Capacity Building for Effective Decentralised Wastewater Management, Swiss Federal Institute of Aquatic Science (EAWAG), Department of Water and Sanitation in Developing Countries (SANDEC) URL [Accessed: 28.05.2019]Compendium of Sanitation Systems and Technologies. 2nd Revised Edition

This compendium gives a systematic overview on different sanitation systems and technologies and describes a wide range of available low-cost sanitation technologies.

TILLEY, E. ULRICH, L. LUETHI, C. REYMOND, P. ZURBRUEGG, C. (2014): Compendium of Sanitation Systems and Technologies. 2nd Revised Edition. Duebendorf, Switzerland: Swiss Federal Institute of Aquatic Science and Technology (Eawag) URL [Accessed: 28.07.2014] PDFCompendium of Sanitation Systems and Technologies

This compendium gives a systematic overview on different sanitation systems and technologies and describes a wide range of available low-cost sanitation technologies.

TILLEY, E. LUETHI, C. MOREL, A. ZURBRUEGG, C. SCHERTENLEIB, R. (2008): Compendium of Sanitation Systems and Technologies. Duebendorf, Switzerland: Swiss Federal Institute of Aquatic Science and Technology (EAWAG) and Water Supply and Sanitation Collaborative Council (WSSCC) URL [Accessed: 15.02.2010] PDFCompendium of Sanitation Systems and Technologies (Arabic)

This is the Arabic version of the Compendium of Sanitation Systems and Technologies. The Compendium gives a systematic overview on different sanitation systems and technologies and describes a wide range of available low-cost sanitation technologies.

TILLEY, E. ULRICH, L. LUETHI, C. REYMOND, P. SCHERTENLEIB, R. ZURBRUEGG, C. (2014): Compendium of Sanitation Systems and Technologies (Arabic). 2nd Revised Edition. Duebendorf, Switzerland: Swiss Federal Institute of Aquatic Science and Technology (Eawag) PDFEmptying on-Site Excreta Disposal Systems. Field Tests with Mechanized Equipment in Gaborone (Botswana)

This report describes field tests of three prototype pit latrine emptying systems, a hand operated diaphgram pump and two vacuum tankers in regular service in Africa. Numerous sludge samples were taken and their viscosities and compositions measured to establish limits for the types of sludges that can be removed by each system.

BOESCH, A. SCHERTENLEIB, R. (1985): Emptying on-Site Excreta Disposal Systems. Field Tests with Mechanized Equipment in Gaborone (Botswana). (= IRCWD-Report 03/85 ). Duebendorf: International Reference Centre for Waste Disposal URL [Accessed: 22.07.2014]Linking Technology Choice with Operation and Maintenance in the context of community water supply and sanitation. A reference Document for Planners and Project Staff

This document is addressed to planners and staff of water supply and sanitation projects on household and community level. The reader is guided through the main steps of informed choices regarding the main proven technologies for water supply, purification and water treatment at household and community level. Each technology is described in a small factsheet, regarding its functioning, actors and their roles, the main operation and maintenance (O&M) requirements and problems, which can occur.

BRIKKE, F. BREDERO, M. (2003): Linking Technology Choice with Operation and Maintenance in the context of community water supply and sanitation. A reference Document for Planners and Project Staff. Geneva: World Health Organization and IRC Water and Sanitation Centre URL [Accessed: 03.06.2018] PDFBusiness Analysis of Fecal Sludge Management: Emptying and Transportation Services in Africa and Asia

This study maps the urban sanitation situation and assesses business and operating models for fecal sludge management in 30 cities across 10 countries in Africa and Asia, specifically focussing on the extraction and transportation market segments.

CHOWDHRY, S. KONE, D. (2012): Business Analysis of Fecal Sludge Management: Emptying and Transportation Services in Africa and Asia. Seattle: Bill & Melinda Gates Foundation URL [Accessed: 22.07.2014]Faecal Sludge Management. Lecture Notes

This module pays special attention to the haulage, treatment and reuse or disposal of faecal sludge. It covers both technical and non-technical (socio-cultural, economic, political etc.) aspects and provides practical information on design, financing and planning of faecal sludge treatment plants.

EAWAG/SANDEC (2008): Faecal Sludge Management. Lecture Notes. (= Sandec Training Tool 1.0, Module 5 ). Duebendorf: Swiss Federal Institute of Aquatic Science (EAWAG), Department of Water and Sanitation in Developing Countries (SANDEC) URL [Accessed: 23.05.2012]Towards an Improved Faecal Sludge Management (FSM)

More than two billion urban dwellers in developing countries use on-site sanitation facilities such as pit latrines, septic tanks and aqua privies for excreta and wastewater disposal. Since on-site sanitation installations will serve the growing urban populations in developing countries for decades to come, increasing faecal sludge quantities will have to be managed. Proper faecal sludge management (FSM) is the important link missing in integrated urban sanitation upgrading efforts.

KONE, D. STRAUSS, M. SAYWELL, D. (2007): Towards an Improved Faecal Sludge Management (FSM). Duebendorf: EAWAG/SANDEC URL [Accessed: 15.12.2010]How to Select Appropriate Technical Solutions for Sanitation

The purpose of this guide is to assist local contracting authorities and their partners in identifying those sanitation technologies best suited to the different contexts that exist within their town. The first part of the guide contains a planning process and a set of criteria to be completed; these assist you in characterizing each area of intervention so that you are then in a position to identify the most appropriate technical solutions. The second part of the guide consists of technical factsheets which give a practical overview of the technical and economic characteristics, the operating principle and the pros and cons of the 29 sanitation technology options most commonly used in sub-Saharan Africa.

MONVOIS, J. GABERT, J. FRENOUX, C. GUILLAUME, M. (2010): How to Select Appropriate Technical Solutions for Sanitation. (= Six Methodological Guides for a Water and Sanitation Services' Development Strategy , 4 ). Cotonou and Paris: Partenariat pour le Développement Municipal (PDM) and Programme Solidarité Eau (pS-Eau) URL [Accessed: 19.10.2011]Investigation into Methods of Pit Latrine Emptying

Many developing countries have embarked on the construction of pit latrines and improved sanitation in people’s homes. An emerging challenge that is resulting from this work is what to do when the latrines are full. If they are to be emptied how should the waste be extracted, where should the waste go and what should be done to it and with it? The approaches to meeting this question are the focus of this report.

O’RIORDAN, M. (2009): Investigation into Methods of Pit Latrine Emptying. Management of Sludge Accumulation in VIP Latrines. (= WRC Project 1745 ). Pretoria: Water Research Commission URL [Accessed: 22.07.2014]Adventures in search of the ideal portable pit-emptying machine

This article explores the ideal portable pit-emptying machine for South Africa owing to site access constraints. The Water Research Commission of South Africa funded experimental development of a number of technologies designed to fill the gap between large vacuum tankers and manual emptying. This paper describes these attempts.

STILL, D. O RIORDAN, M. MC BRIDE, A. LOUTON, B. (2013): Adventures in search of the ideal portable pit-emptying machine. Rugby: Practical Action Publishing URL [Accessed: 07.08.2013]Faecal Sludge Management

This is the first book to compile the current state of knowledge on faecal sludge management. It addresses the organization of the entire faecal sludge management service chain, from the collection and transport of sludge, to the current state of knowledge of treatment options, and the final end use or disposal of treated sludge. It presents an integrated approach that brings together technology, management, and planning, based on Sandec’s 20 years of experience in the field. It also discusses important factors to consider when evaluating and upscaling new treatment technology options. The book is designed for undergraduate and graduate students, engineers, and practitioners in the field who have some basic knowledge of environmental and/or wastewater engineering.

STRANDE, L. ; RONTELTAP, M. ; BRDJANOVIC, D. (2014): Faecal Sludge Management. Systems Approach for Implementation and Operation. London: IWA Publishing URL [Accessed: 16.07.2014]FS Management – Review of Practices, Problems and Initiatives

A study on management and institutional aspects regarding the challenges and possible improvements in managing faecal sludge.

STRAUSS, M. MONTANGERO, A. (2002): FS Management – Review of Practices, Problems and Initiatives. London and Duebendorf: DFID Project R8056, Capacity Building for Effective Decentralised Wastewater Management, Swiss Federal Institute of Aquatic Science (EAWAG), Department of Water and Sanitation in Developing Countries (SANDEC) URL [Accessed: 28.05.2019]Compendium of Sanitation Systems and Technologies

This compendium gives a systematic overview on different sanitation systems and technologies and describes a wide range of available low-cost sanitation technologies.

TILLEY, E. LUETHI, C. MOREL, A. ZURBRUEGG, C. SCHERTENLEIB, R. (2008): Compendium of Sanitation Systems and Technologies. Duebendorf, Switzerland: Swiss Federal Institute of Aquatic Science and Technology (EAWAG) and Water Supply and Sanitation Collaborative Council (WSSCC) URL [Accessed: 15.02.2010] PDFSanitation partnerships. Harnessing their potential for urban on-site sanitation

The aim of this case study in five African cities was to look closely at the issue, see where partnerships fit into efforts to improve on-site sanitation and understand better what makes them succeed or fail. The ultimate goal is to help those involved in the delivery of sanitation services make more informed decisions about what routes to pursue the outset

SCHAUB-JONES, D. EALES, K. TYERS, L. (2006): Sanitation partnerships. Harnessing their potential for urban on-site sanitation. URL [Accessed: 15.12.2010]Inefficient technology or misperceived demand

Demand is growing globally for appropriate technology and viable business solutions to pit-emptying and transportation services. There is a growing body of experiments on technological innovations in different contexts to find an effective solution. However, there is no one technology or business model that can be applied everywhere because of contextual difference and varied demand. A Vacutug-based emptying and transportation service has been introduced in an urban context in Bangladesh by WaterAid. However, this study suggests that despite enormous demand, this mechanical emptying and transportation service has not been successful because of technological inefficiency and other demand-related factors.

OPEL, A. BASHAR, M.K. (2013): Inefficient technology or misperceived demand. The failure of Vacutug-based pit-emptying services in Bangladesh. Rugby: Practical Action Publishing URL [Accessed: 07.08.2013]Emptying Pit Latrines

This technical brief describes several possibilities of emptying pit latrines and helps to find the most suitable method.

PICKFORD, J. SHAW, R. (1997): Emptying Pit Latrines. (= Technical Briefs, No. 54 ). Loughborough: Water and Environmental health at London and Loughborough (WELL) URL [Accessed: 28.05.2019]http://www.un-habitat.org/

After studying the situation in slums around the world, UN-HABITAT sought to devise a system that would replace manual pit latrine and septic tank emptying. It commissioned a mechanical system that would be capable of being manufactured locally using readily available components, that would be affordable, easily serviceable, able to operate in narrow passageways where other conventional exhauster vehicles cannot pass, and capable of sucking out dense waste sludge for transportation to a larger tanker vehicle. At the same time it was imperative that excrement be removed as safely as possible without posing further health hazards in slums. Thus in 1995 Manus Coffey and Associates Ltd (MCA) and UN-HABITAT designed and built the first prototype in Ireland: the MK I UN-HABITAT Vacutug.