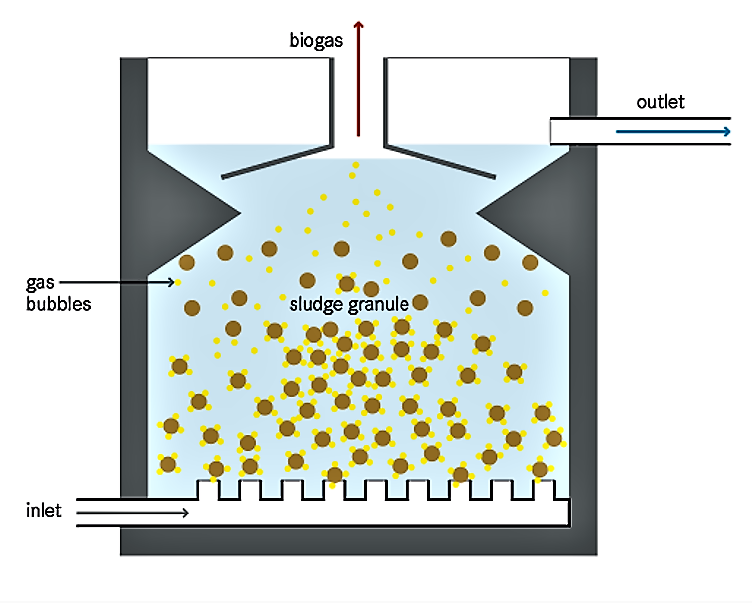

The upflow anaerobic sludge blanket reactor (UASB) is a single tank process. Wastewater enters the reactor from the bottom, and flows upward. A suspended sludge blanket filters and treats the wastewater as the wastewater flows through it.

| In | Out |

|---|---|

Digested Faecal Sludge, Fertigation Water |

The sludge blanket is comprised of microbial granules (1 to 3 mm in diameter), i.e., small agglomerations of microorganisms that, because of their weight, resist being washed out in the upflow. The microorganisms in the sludge layer degrade organic compounds. As a result, gases (methane and carbon dioxide) are released. The rising bubbles mix the sludge without the assistance of any mechanical parts. Sloped walls deflect material that reaches the top of the tank downwards. The clarified effluent is extracted from the top of the tank in an area above the sloped walls.

After several weeks of use, larger granules of sludge form which, in turn, act as filters for smaller particles as the effluent rises through the cushion of sludge. Because of the upflow regime, granule-forming organisms are preferentially accumulated as the others are washed out.

Critical elements for the design of UASB reactors are the influent distribution system, the gas-solids separator, and the effluent withdrawal design. The gas that rises to the top is collected in a gas collection dome and can be used as energy (see also use of biogas). An upflow velocity of 0.7 to 1 m/h must be maintained to keep the sludge blanket in suspension. Primary settling is usually not required before the UASB.

Let's try this!

The operators should take proper health and safety measures while working in the plant, such as adequate protective clothing. Effluent and sludge still pose a health risk and should not be directly handled.

The UASB is a Centralized Treatment technology that must be operated and maintained by professionals. A skilled operator is required to monitor the reactor and repair parts, e.g., pumps, in case of problems.

Desludging is infrequent and only excess sludge is removed every 2 to 3 years.

A UASB is not appropriate for small or rural communities without a constant water supply or electricity. The technology is relatively simple to design and build, but developing the granulated sludge may take several months. The UASB reactor has the potential to produce higher quality effluent than Septic Tanks, and can do so in a smaller reactor volume. Although it is a well-established process for large-scale industrial wastewater treatment and high organic loading rates up to 10 kg BOD/m3/d, its application to domestic sewage is still relatively new. It is often used for brewery, distillery, food processing and pulp and paper waste since the process typically removes 80 to 90% of COD. Where the influent is low-strength or where it contains too many solids, proteins or fats, the reactor may not work properly. Temperature is also a key factor affecting the performance.

Anaerobic Treatment of Raw Domestic Sewage at Ambient Temperatures Using a Granular Bed UASB Reactor

Biological Wastewater Treatment in Warm Climate Regions Volume 1

Biological Wastewater Treatment in Warm Climate Regions gives a state-of-the-art presentation of the science and technology of biological wastewater treatment, particularly domestic sewage. The book covers the main treatment processes used worldwide with wastewater treatment in warm climate regions given a particular emphasis where simple, affordable and sustainable solutions are required. The 55 chapters are divided into 7 parts over two volumes: Volume One: (1) Introduction to wastewater characteristics, treatment and disposal; (2) Basic principles of wastewater treatment; (3) Stabilisation ponds; (4) Anaerobic reactors; Volume Two (also available in the SSWM library): (5) Activated sludge; (6) Aerobic biofilm reactors; (7) Sludge treatment and disposal.

SPERLING, M. von LEMOS CHERNICHARO, C.A. de (2005): Biological Wastewater Treatment in Warm Climate Regions Volume 1. London: International Water Association (IWA) Publishing URL [Accessed: 26.05.2019]UASB Technology-expectations and reality

This paper highlights some inherent lacunae of UASB technology for sewage treatment based on a set of case studies, effluent data of UASB systems and a long-term monitoring of the performance of pilot plants in Kantapur (India).

TARE, V. NEMA, A. (n.y): UASB Technology-expectations and reality. United Nations Asian and Pacific Centre for Agricultural Engineering and Machinery URL [Accessed: 29.04.2010]Wastewater Engineering, Treatment and Reuse

Compendium of Sanitation Systems and Technologies. 2nd Revised Edition

This compendium gives a systematic overview on different sanitation systems and technologies and describes a wide range of available low-cost sanitation technologies.

TILLEY, E. ULRICH, L. LUETHI, C. REYMOND, P. ZURBRUEGG, C. (2014): Compendium of Sanitation Systems and Technologies. 2nd Revised Edition. Duebendorf, Switzerland: Swiss Federal Institute of Aquatic Science and Technology (Eawag) URL [Accessed: 28.07.2014] PDFEnvironmental Sanitation Reviews. Anaerobic Wastewater Treatment – Attached Growth and Sludge Blanket Process

The paper provides a good technical overview over the attached growth and sludge blanket process in anaerobic wastewater treatment.

VIGNESWARAN, S. BALASURIYA, B. L. N. VIRARAGHAVAN, T. (1986): Environmental Sanitation Reviews. Anaerobic Wastewater Treatment – Attached Growth and Sludge Blanket Process. Bangkok: Environmental Sanitation Information Center (ENSIC)