Pumping stations in a water distribution system are necessary where water is pumped directly into the system (e.g. from a lake) or where pressure has to be increased because there is an insufficient difference in water levels in gravity flow distribution systems. There are two general types of pumps: vertical turbine pumps and centrifugal pumps. Capital costs are high, but the most expensive part is the energy supply for pumps (mostly electrical). Therefore, it is very important that pumps have a high degree of efficiency and are maintained properly. To guarantee safewater quality, cross connection of drinking water and waste removal systems must be avoided.

| In | Out |

|---|---|

Freshwater, Drinking Water |

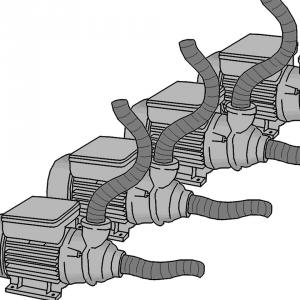

Pumps are devices used to transfer water from point A to point B with pressure to overcome the resistance along its path. It is important to understand the different types of pumps, their applications, design differences and the procedures used to operate and maintain them (THE WORLD BANK 2012). Pumping stations are used for reliable and efficient transport and distribution of fresh water to guarantee the availability for human, industrial, and agricultural use (ABB 2012) (see also water use).

Adapted from GUYER (2012)

Main pumping stations, which supply water to the distribution system, are located near the water treatment facility or a potable water storage facility, and pump directly into the piping system. Pumps that pump directly into transmission lines and distribution systems are sometimes called high lift pumps.

Booster pumps are additional pumps used to increase pressure locally or temporarily. Booster pumps stations are usually remotely located from the main pump station, as in hilly topography where high-pressure zones are required, or to handle peak flows in a distribution system that can otherwise handle the normal flow requirements.

Where a pump station is added to an existing installation, previous planning and design, which are based upon a total system hydraulic analysis, should be consulted before the addition is designed (see also network design and dimensioning).

The sizing of each component in the distribution system will depend upon the effective combination of the major system elements:

- Supply source

- Storage (e.g. in reservoirs)

- Distribution piping

- Pumping

The location of the pump station and intake structure (see also water extraction from lakes and rivers), and the anticipated heads and capacities are the major factors in the selection of pumps. The function of a pump station in the overall distribution system operation can also affect the determination of capacities.

Pump types

Adapted from GUYER (2012)

There are generally two types of pumps used for potable water pumping applications.

- The vertical turbine pump (line shaft and submersible types)

- The centrifugal horizontal or vertical split case pump designed for water-works service.

You can also find more specific information about pumps in: THE WORLD BANK (2012) (see Chapter 14).

Pump discharge capacity

Adapted from THE WORLD BANK (2012)

- If the pump is used directly to supply water without a reservoir, the capacity must be equal to the peak hour demand.

- If the water distribution system has a reservoir, the pump capacity must be equal to the maximum daily demand.

Pump selection

Adapted from THE WORLD BANK (2012)

- If the pumping water level is less than 6 metres, use a centrifugal pump (maximum suction lift = 6 metres).

- If the pumping water level is from 6-20 metres, use jet pumps or a submersible.

- If the PWL is greater than 20 metres, use a submersible or a vertical line shaft turbine pump.

Power supply for pumps

Adapted from THE WORLD BANK (2012)

Electric, gasoline or diesel engines are commonly used as power sources for pumps. The electric motor is, however, the most favoured power source because of its reliability, relatively low power cost, and environmental considerations like cleanliness, relatively low noise, and low pollutant emissions. An electrical pump may also be driven with solar power. Heat sensors installed in the windings during manufacturing should protect electric motors. These sensors shut the motor off in case of low voltage or change in phase before damage can be done.

A pumping station only makes sense if there is a properly planned distribution network. This needs a lot of construction material, electricity, maintenance, and of course, expert design. Moreover, the construction and installation costs are high. Therefore, the whole system is rather expensive and only sustainable if operation and maintenance can be ensured (see also operation and maintenance or ensuring sustainability).

The energy cost is one of the largest cost components in the water supply system. Since large amounts of electricity are required to pump, transport and supply water, the profitability of some businesses, such as irrigation districts or fish farms, which use the water as a production resource, is heavily dependent upon energy costs (PULIDO-CALVO & GUTIERREZ-ESTRADA 2011).Therefore, it is very important that the degree of efficiency of the pumps is very high. In Switzerland, for example, the highly developed water distribution system requires 1/5 of the public power consumption (SCHNEEMANN 2011).

A cross-connection of drinking water distribution and waste removal system must be avoided. This risk is usually greater in public, industrial and commercial premises, where dual water systems, circulating pumps, toxic wastes and other factors have to be managed. There are also risks in multi-storey buildings where booster pumps are employed to increase the mains pressure, and in special systems used in hospitals and in dental and veterinary surgeries. However, even standard single-family domestic buildings present health risks to both occupants and neighbours if faulty plumbing is installed or if plumbing is not maintained (WHO 2006). See preventing recontamination for more information.

Pump controls can be manual or automatic. For small systems, manual controls can work very well. The operators can start the pump in the morning, and with some operational experience, they will be able to estimate the time required to satisfy the morning peak demand and to fill the tank. When the tank is full, the pump is shut off. The pump is started again when the water level in the tank decreases to the minimum water level. With automatic control, the pump’s start and shutoff is triggered either by floats or by pressure without requiring an operator to assume or estimate pumping cycle schedules (THE WORLD BANK 2012). Pumps need mechanical maintenance (e.g. lubrication) as the manufacturer requests it.

| Working principle | Main pumping stations pump water directly into the distribution system. Booster pumps help to increase pressure in a system, e.g. pumping water from ground to roof. |

| Capacity/adequacy | Necessary for piped distribution systems. |

| Performance | High if pumps are effective. |

| Costs | High (especially power supply). |

| Self-help compatibility | Expert design and construction supervising are required. |

| O&M | Manual (for small scale distribution systems) or automatic pump control. |

| Reliability | If well maintained and constructed, high. |

| Main strength | Provides a constant pressure in a piped distribution system even during high peak flow. |

| Main weakness | High capital and electrical costs. |

Pumping stations are necessary where large amounts of water have to be transported through a piped distribution system. Booster pumps are needed where water pressure in a distribution system has to be increased (e.g. pumping from a ground level or basement gravity tank to a gravity roof tank) (WHO 2006).

Products and Solutions for Pumping Stations. Enhanced Plant Performance, Efficiency and Reliability

A short paper about ABB’s products and solutions for pumping stations and some large scale examples.

ABB (2012): Products and Solutions for Pumping Stations. Enhanced Plant Performance, Efficiency and Reliability. Switzerland: ABB Switzerland URL [Accessed: 04.08.2012]Introduction to Pumping Stations for Water Supply Systems

This document provides guidance and criteria for the design of high lift and water booster pumping stations in potable water distribution systems.

GUYER (2012): Introduction to Pumping Stations for Water Supply Systems. Stony Point (NY): Continuing Education and Development (CED), Inc URL [Accessed: 07.05.2012]Selection and Operation of Pumping Stations of Water Distribution Systems

The energy cost is one of the most important cost components in water supply systems. Since large amounts of electricity are required to pump, transport and apply water, the profitability of some business, as irrigation districts or fishfarms, which use water as a production resource, is heavily dependent upon energy costs. Methodologies that can maximize energy cost savings while satisfying system performance criteria should be sought for the design and management of the water distribution systems. Some of these methods can be: (a) to improve the selection and/or operation of pumping stations; and (b) to include a regulating reservoir between the water supply source and the delivery system. In this chapter, one model that includes both alternatives is presented.

PULIDO-CALVO, I. ; GUTIERREZ-ESTRADA, J.C. (2011): Selection and Operation of Pumping Stations of Water Distribution Systems. In: Environmental Research Journal: Volume 5 , 1-20. URL [Accessed: 07.05.2012]Rural Water Supply Design Manual. Volume I

This RURAL WATER SUPPLY DESIGN MANUAL is the first of three related volumes prepared for the use of prospective and actual owners, operators, managements, technical staff, consultants, government planners and contractors of small Level III and Level II water supply systems in the Philippines.

THE WORLD BANK (2012): Rural Water Supply Design Manual. Volume I. Manila: The World Bank Office Manila URL [Accessed: 11.03.2019] PDFEffiziente Trinkwasserpumpenhelfen Strom und Geld sparen

Health Aspects of Plumbing

This publication describes the processes involved in the design, installation and maintenance of effective plumbing systems. It recommends a number of plumbing system designs and installation specifications.

WHO (2006): Health Aspects of Plumbing. Geneva: World Health Organisation (WHO) URL [Accessed: 24.03.2011]Water System Design

This manual provides guidelines and criteria for design engineers to use for preparing plans and specifications for Group A water systems to comply with the Group A Public Water Supplies. Group A water systems typically serve drinking water to 15 or more connections. This manual also clarifies the engineering document submission and review requirements.

DOH (2009): Water System Design. Tumwater: Washington State Department of Health (DOH) URL [Accessed: 09.10.2012]Introduction to Pumping Stations for Water Supply Systems

This document provides guidance and criteria for the design of high lift and water booster pumping stations in potable water distribution systems.

GUYER (2012): Introduction to Pumping Stations for Water Supply Systems. Stony Point (NY): Continuing Education and Development (CED), Inc URL [Accessed: 07.05.2012]Selection and Operation of Pumping Stations of Water Distribution Systems

The energy cost is one of the most important cost components in water supply systems. Since large amounts of electricity are required to pump, transport and apply water, the profitability of some business, as irrigation districts or fishfarms, which use water as a production resource, is heavily dependent upon energy costs. Methodologies that can maximize energy cost savings while satisfying system performance criteria should be sought for the design and management of the water distribution systems. Some of these methods can be: (a) to improve the selection and/or operation of pumping stations; and (b) to include a regulating reservoir between the water supply source and the delivery system. In this chapter, one model that includes both alternatives is presented.

PULIDO-CALVO, I. ; GUTIERREZ-ESTRADA, J.C. (2011): Selection and Operation of Pumping Stations of Water Distribution Systems. In: Environmental Research Journal: Volume 5 , 1-20. URL [Accessed: 07.05.2012]Rural Water Supply Design Manual. Volume I

This RURAL WATER SUPPLY DESIGN MANUAL is the first of three related volumes prepared for the use of prospective and actual owners, operators, managements, technical staff, consultants, government planners and contractors of small Level III and Level II water supply systems in the Philippines.

THE WORLD BANK (2012): Rural Water Supply Design Manual. Volume I. Manila: The World Bank Office Manila URL [Accessed: 11.03.2019] PDFHealth Aspects of Plumbing

This publication describes the processes involved in the design, installation and maintenance of effective plumbing systems. It recommends a number of plumbing system designs and installation specifications.

WHO (2006): Health Aspects of Plumbing. Geneva: World Health Organisation (WHO) URL [Accessed: 24.03.2011]Products and Solutions for Pumping Stations. Enhanced Plant Performance, Efficiency and Reliability

A short paper about ABB’s products and solutions for pumping stations and some large scale examples.

ABB (2012): Products and Solutions for Pumping Stations. Enhanced Plant Performance, Efficiency and Reliability. Switzerland: ABB Switzerland URL [Accessed: 04.08.2012]Water our most Essential Resource

Safe, reliable, and abundant water has been at the centre of Winnipeg’s success for more than 80 years. Read more about the history of a big city’s water distribution network.

WATER AND WASTE DEPARTMENT (2002): Water our most Essential Resource. Winnipeg: Water and Waste Department URL [Accessed: 07.05.2012]