Sewer pumping stations (also called lift stations) are used to move wastewater to higher elevations in order to allow transport by gravity flow. Sewage is fed into and stored in a sealed underground pit, commonly known as a wet well. When the level rises to a predetermined point, a pump will be started to lift the sewage upward through a pressurised pipe system from where it is discharged into a gravity manhole again. From here the cycle starts all over again until the sewage reaches its point of destination – usually a treatment plant.

| Entradas | Salidas |

|---|---|

Blackwater, Faecal Sludge, Greywater, Brownwater, Urine or Yellowwater, Faeces, Energy |

Blackwater, Faecal Sludge, Greywater, Brownwater, Urine or Yellowwater, Faeces |

Pumping stations in sewage collection systems, also called lift stations, are designed to handle raw sewage that is fed from underground gravity pipelines. They are used to move wastewater to higher elevations. In general, the need for sewer pumping stations arises when (EESD 2003):

- The existing topography and required minimum sewer grades create deep sewers that have high construction costs. The sewage is raised and then conveyed by gravity.

- Basements are too low to discharge sewage to the main sewer.

- Sewage must be conveyed over a ridge.

- The sewage must be raised to get head for gravity flow through a treatment plant.

- Discharge outlets are below the level of the receiving body of water.

- An existing gravity system is not yet available. A pumping station will enable development and growth in accordance with the applicable community plan.

Sewage is fed into and stored in an underground pit, commonly known as a wet well. Electrical instrumentation is installed to detect the level of sewage (and if necessary to activate an alarm if there are any technical problems). When the level rises to a predetermined point, a pump will be started to lift the sewage upward through a pressurised pipe system (sewer force main or rising main) from where it is discharged into a gravity manhole again. From here, the cycle starts all over again until the sewage reaches its point of destination – usually a treatment plant (WIKIPEDIA 2010). To learn more about sewer systems see also conventional sewers, separate sewers or pressurised sewers.

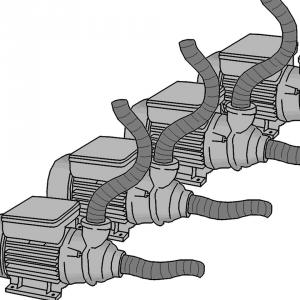

Sewage pumps are almost always end-suction centrifugal pumps with open impellers and are specially designed with a large open passage so as to avoid clogging (WIKIPEDIA 2011).Common problems are siltation, fat build up and blockages. To minimise siltation, where benching is unlikely to be self-cleansing, an automatic wet well flushing & mixing system is to be provided. Fat build up can be reduced using the facilities of the ultrasonic unit by setting a variable range of top water levels for pump starts, to prevent a ring of fat forming (UNITED UTILITIES 2006).

The volume of the wet well shall be based on the design average flow with a filling time of a minimum of 30 minutes between the firm capacity start and by-pass. Factors to consider when determining the size are (EESD 2003):

- The volume required for pump cycling based on the pump manufacturer’s duty cycle recommendations.

- Appropriate dimensions to minimise turbulence.

- Vertical separation between pump control points.

- Sewer inlet elevation.

- Capacity required between alarm levels, basement flooding and overflow elevations.

- The number, spacing and size of pumps. The wet well floor shall have adequate slope to the intake hopper and the horizontal area of the hopper shall be kept to a minimum.

- Minimise pump starts and stops (reducing energy use), while avoiding to long retention time because the sewage in the wet well will become septic.

A pumping station is always in combination with a (on-site or semi-centralised) treatment plant and/or a sewer system. This needs a lot of construction material, electricity, maintenance and of course expert design. Also the construction and installation costs are high. Therefore the whole system it is a very expensive and neither a very suitable nor a sustainable solution in developing countries.

The system is mostly computer- or electronically monitored. Sensors check the sewage level of the wet wells and start/stop the pumps. The pumps ad its monitoring unit should be maintained periodically by the supplier.

Sewer system technology in general provides a high level of hygiene and comfort. If the sewerage is transported in a closed system and is able to convey higher elevations without any problems and without directly involved workers, makes it even more secure. Overflows of wet wells should be avoided and it is important that there is a treatment plant at the end of every sewer system.

| Working principle | Sewage is fed into and stored in a sealed underground pit, commonly known as a wet well. When the level rises to a predetermined point, a pump will be started to lift the sewage upward through a pressurised pipe system from where it is discharged into a gravity manhole again. |

| Capacity/adequacy | Especially appropriate for dense, urban areas where are differences of altitude in the topography. |

| Performance | Big loads of sludge can be transported to higher elevations in a closed system. |

| Costs | Capital costs for a whole sewer system including pumping stations are very high. |

| Self-help compatibility | Expert design and construction supervising are required. Can be constructed with locally available material. |

| O&M | The system is mostly computer- or electronically monitored. Sensors check the sewage level of the wet wells and start/stop the pumps. The pumps ad its monitoring unit should be maintained periodically by the supplier. |

| Reliability | If well maintained and constructed, high. |

| Main strength | Sewage can be pumped automatically to higher elevations. No contact with wastewater is necessary.

|

| Main weakness | It needs expert design, maintenance and operation and capital costs are very high; requires power. |

Pumping stations become necessary as soon as sewage has to be lifted from a lower part to a higher part. Therefore, a well constructed piping system (e.g. conventional sewer system) and a treatment plant, where the wastewater can be treated in a proper way is necessary. Moreover, construction material and spare parts is expensive and might be difficult to acquire locally.

Design Specification & Requirements Manual. Updated 2010

Among other things, there is much information about the sewer collection system in the City of London, (Ontario-Canada). There will be site-specific situations where the design will depart from these practices as it is not possible nor is it the intention of the City to anticipate every situation.

EESD (2003): Design Specification & Requirements Manual. Updated 2010. 4 Sewage Pumpoing Stations. London, Ontario (Canada): Environmental and Engineering Services Department (EESD) URL [Visita: 30.05.2019]Pump Stations

Anlagen zur Abwasserbeseitigung

Sewers for Adoption 6th Edition United Utilities Guidelines Pumping Stations For Adoption

This document is intended to advise developers of United Utilities’ specific requirements in relation to pumping stations. All important points of a sewer pumping station are described in short paragraphs.

UNITED UTILITIES (2006): Sewers for Adoption 6th Edition United Utilities Guidelines Pumping Stations For Adoption. Warrington: United Utilities Group PLC. [Accessed: 03.03.2011] PDFDesign Specification & Requirements Manual. Updated 2010

Among other things, there is much information about the sewer collection system in the City of London, (Ontario-Canada). There will be site-specific situations where the design will depart from these practices as it is not possible nor is it the intention of the City to anticipate every situation.

EESD (2003): Design Specification & Requirements Manual. Updated 2010. 4 Sewage Pumpoing Stations. London, Ontario (Canada): Environmental and Engineering Services Department (EESD) URL [Visita: 30.05.2019]Sewers for Adoption 6th Edition United Utilities Guidelines Pumping Stations For Adoption

This document is intended to advise developers of United Utilities’ specific requirements in relation to pumping stations. All important points of a sewer pumping station are described in short paragraphs.

UNITED UTILITIES (2006): Sewers for Adoption 6th Edition United Utilities Guidelines Pumping Stations For Adoption. Warrington: United Utilities Group PLC. [Accessed: 03.03.2011] PDFDesign Specifications and Requirements Manual

Among other things, there is much information about the sewer collection system in the City of London, ON. There will be site specific situations where the design will depart from these practices as it is not possible nor is it the intention of the City to anticipate every situation.