Water savings can be achieved in industry through a combination of changing behaviour, modifying and/or replacing equipment with water saving equipment to reduce overall water consumption and increase internal reuse. To assure the strategies, optimise water and minimise costs, it is important to assess current water use and set goals. Reducing industrial water consumption is a means of addressing the global water crisis. As of 1999, industrial water use accounted for 5-10% of global freshwater withdrawals. The majority of all industrial water use is from the cooling of power plants. This factsheet provides an overview of how to save and use water more efficiently in industries.

| In | Out |

|---|---|

Precipitation, Freshwater, Drinking Water, Blackwater,Greywater,Fertigation Water, Treated Water |

Blackwater, Greywater, Fertigation Water,Treated Water, Energy |

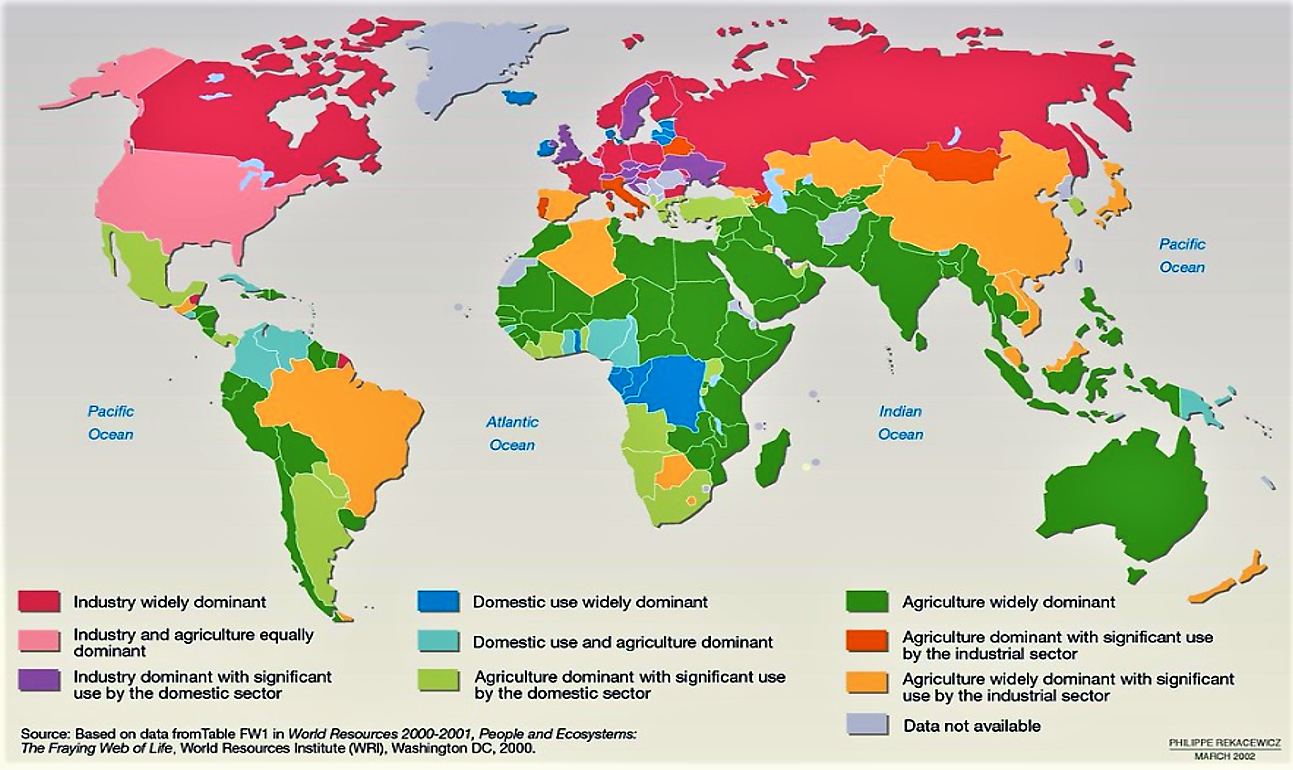

There is incredible competition between the water needs of agriculture, industry, and the growing number of people in our world, and there are severe and increasing freshwater shortages in many areas. Indices and maps of water scarcity have been drawn up and there is talk of the “water crisis", and predictions of increasing number of water conflicts (adapted from GROBICKI (2008)).

Adapted from UNESCO (2009)

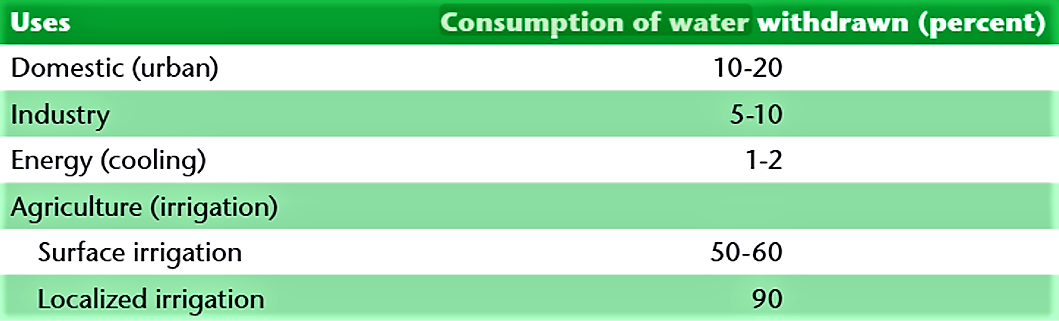

The consumptive uses of freshwater from agriculture, industry and domestic sector place the greatest pressures on natural systems, both in quantity (withdrawals) and quality (impact of wastewater discharges). After agriculture, the two major users of water for development are industry and energy (20% of total water withdrawals), which are transforming the patterns of water use in emerging market economies. Water and energy share the same drivers: demographic, economic, social and technological processes.

In 2009, European and North American industrial water use accounted for half of their total water use, whereas in developing nations industrial water use ranges from 4-12% of national water use. As industrialisation in developing nations increases, industrial water use could potentially increase by a factor of five.

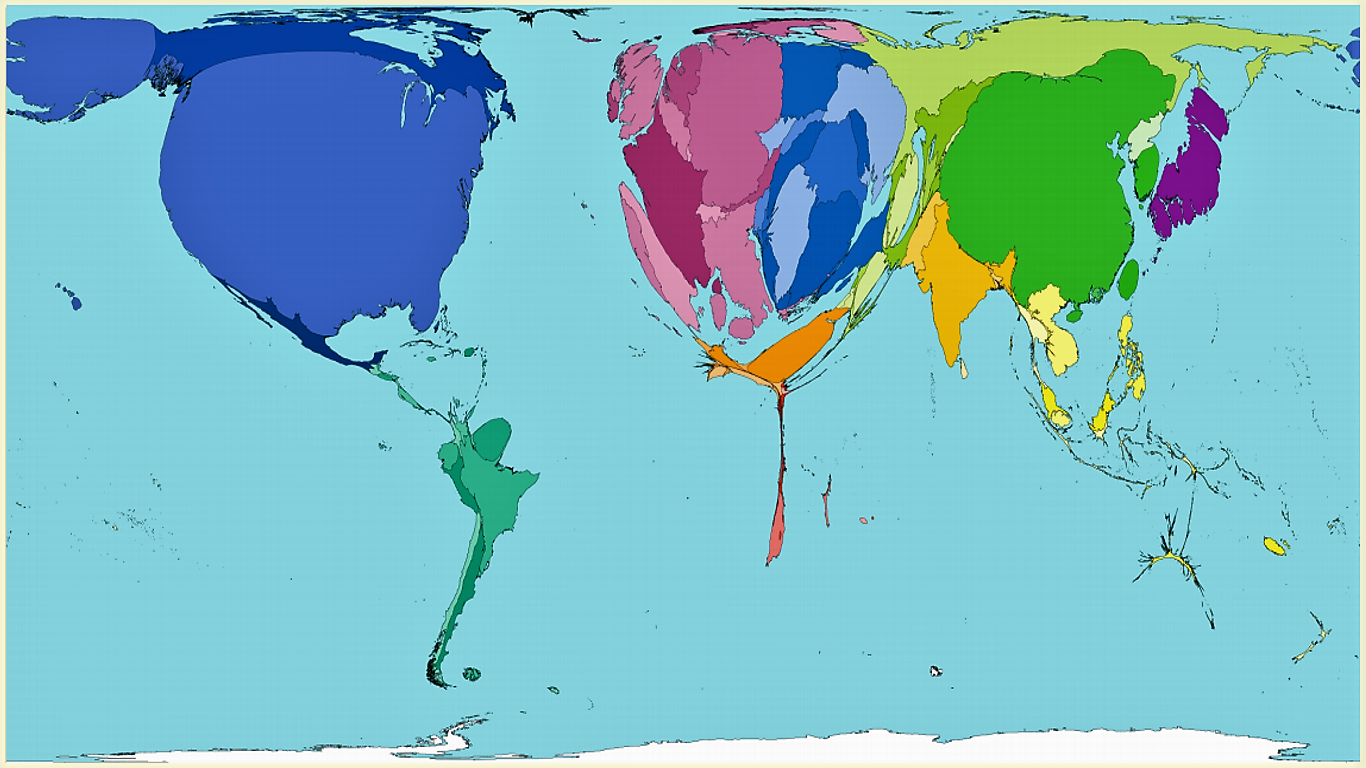

Optimisation of water use by industries is important because it can lower water withdrawals from local water sources thus increasing water availability and improving community relations, increasing productivity per water input, lowering wastewater discharges and their pollutant load, reducing thermal energy consumption and, potentially, processing cost. From 1987 to 2003, industry used roughly twice as much water as households, where about a third of this water usage was recorded in the United States and only about a thirtieth by all 19 territories of Southeastern Africa combined (SASI & NEWMAN 2006).

Industry puts pressure on water resources more by the impact of wastewater discharges and their pollution potential than by the quantity used in production (UNESCO 2009). Most industries generate pollutants as by-products of their producing activities, the major pollutants being nutrients, pathogens, heavy metals, organic and inorganic chemicals, oil sediments and heat (see also water pollution and pathogens and contaminants). Heat as a thermal pollutant occurs if the water discharges of the industry change the ambient temperature of the water body. As water temperature increases, the amount of dissolved oxygen in the water decreases. Low oxygen levels in water bodies can be harmful to aquatic creatures. Temperature changes of just one degree can trigger subtle changes in the biology of aquatic organisms, causing them to change their metabolism or plant growth (KENNISH 1992).

Creating incentives in terms of economic tools and command and control tools is crucial in order to support the creation of an enabling environment for water use optimisation in industries.

However, creating incentives for behaviour changes can be very difficult when the results are not felt by the users. Awareness raising among operators to use water-efficient strategies and/or equipment, and structuring rewards and competitions to optimise water use helps in changing the user behaviour (see also the developing human resources section). Demand creation is an important aspect of changing users’ behaviour. Training programmes can be evaluated to determine effectiveness and continually improve the protocol. Several for-profit companies and universities are designing competitions and feedback mechanisms to make users aware of water and energy use in real time (see also MELTON 2012).

Educate Employees and Set Up a Water Conservation Programme

Adapted from CONSERVE WATER GEORGIA (2009)

- Build understanding among employees and co-workers about the importance of water conservation. Make them aware of water scarcity issues and the impact of water conservation practices.

- Educate employees so that they will be able to identify problems and innovate solutions to reduce water use within the company.

- Engage employees in problem-solving to reduce water usage.

Assess Current Water Use

Adapted from CONSERVE WATER GEORGIA (2009)

It is often useful to appoint a person in charge of coordinating the water reduction process. Use the information gathered through the assessment process to develop water reduction goals. See implementation support tools for more information on how to implement specific measures.

- Read your water and sewer bills to determine how much water is currently used and to identify peaks.

- Apply submetering to determine use by location or equipment.

- Calculate average water use by department or process. Rank processes/departments by water use to determine where to focus conservation goals.

- Survey plant operations to determine areas where water is wasted or could be reused.

- Check piping regularly and identify leaks.

Some typical operational changes for reducing water consumption at the operational level are developing a regular inspection programme for piping and hoses, reducing water consumption for cleaning (including switching to dry technologies) and finding multiple uses for water. In order for operational changes to be successful, the changes must be thoroughly planned, well implemented and followed by evaluating and monitoring activities to ensure sustainability in the long term.

Inspection Programme for Piping and Hoses

Adapted from CONSERVE WATER GEORGIA (2009)

If the average water use (base level) is measured for all operational activities separately, the identification of leaks is simple: wherever water consumption rises above the base level, the presence of some form of water loss (e.g. a leak) is likely.

- To locate leaks use submeters to look for a trend of increased usage that cannot be associated with increased production activities.

- Conduct regular inspection of equipment or areas where leaks could occur, like pipe-work joints, connections and fittings. Indications include dampness, rust marks or swelling boards. Significant leaks can often be detected by listening in the absence of other noises.

- Check equipment in addition to pipes and hoses.

- Install monitoring or sub-meter systems that alert operators when excessive flows or reduced pressures breach normal ranges.

- For concealed or subsurface pipe-work, leakage detection companies can employ techniques such as pressure testing, flow monitoring and echo correlation.

Minimise Water Use for Cleaning

Adapted from CONSERVE WATER GEORGIA (2009)

Water use for cleaning can be further reduced if water from internal processes is used for cleaning. Depending on the water quality required for cleaning, this might require greywater treatment.

Indoors

- Use brooms, squeegees and dry vacuum cleaners to clean surfaces before washing with water.

- Use washing equipment that has aerated spray nozzles with shut-off valves.

- Fit hoses with high-pressure, low-volume nozzles with shut-off valves.

- Where possible, mop floors instead of hosing.

- Switch from wet carpet cleaning methods (e.g. steam cleaning) to dry power methods or spot cleaning.

Outdoors

- Sweep parking, paved, plant and path areas rather than hosing, unless it is required for health regulations.

- Reconsider the need to wash building exteriors or other outside structures.

- Reduce the frequency of cleaning external equipment and floors where possible.

- Change window-cleaning schedules from 'regular' to 'as required' and use squeegees.

- Wash vehicles only as needed.

- Limit the use of high-pressure sprayers, unless they are needed to protect human health and maintain safety.

- For equipment that needs to be cleaned regularly, consider using process water from other areas. Reusing water within a business can dramatically reduce water consumption.

- Consider alternative methods of cleaning, such as high-pressure air jets and/or vacuums.

- Where possible, wash items in water baths rather than under sprinklers.

- Agitate rinse baths with air or mechanically, to increase rinse water life and efficiency.

- Use scrapers and brooms to remove residue build-up in plant machinery.

- Regularly check that spray nozzles are aimed correctly.

Adapted from CONSERVE WATER GEORGIA (2009)

A small modification in existing equipment can result in substantial water savings.

- Install trigger-operated guns on hoses so that operators can use less water during clean up.

- Change taps, nozzles and shower fixtures to high pressure, low volume alternatives.

- Add timers and/or pedals to assure water is used sparingly and efficiently.

- Adjust flows to the minimum required to maintain performance.

- Install submetering systems.

- Install in-line strainers on sprayer heads.

- Adjust pump cooling and water flushing to minimum required for operations.

Water Saving Equipment

The most popular water saving equipment for oil industries is reusing process water for cooling towers (MCYINTIRE 2006). To achieve significant water savings, a greywater treatment system can treat process water to allow internal reuse. New equipment should be partnered with an awareness raising campaign to assure operators optimise water usage.

- As appliances and equipment wear out, replace them with water-saving models.

- Install water saving toilet systems (e.g. low flush, vacuum, dehydration, or composting toilets), adjust flush valves.

- Install tap aerators and high efficiency showerheads.

- Choose conveying systems that use water efficiently.

- Replace high-volume hoses with high-pressure, low-volume cleaning systems.

Finding Water Saving Equipment

There are several labelling programmes to help users find and identify water saving equipment. Not all products have such labelling and it is best to compare expected water use with current water use of existing equipment. In the US, the WaterSense Label exists for identifying water efficient products (see below in “important weblinks”).

Instead of assuming that all processes require drinking quality water, investigate actual water quality needed for internal processes and reuse water within the business or between businesses whenever possible. For example, a polishing machine may require water with a certain particulate level. If a settling tank and greywater treatment was installed, the polishing machine could technically reuse its own water an infinite number of times.

Possible treatment options for water reuse include: waste stabilisation ponds, aerated ponds, trickling filters, vertical flow constructed wetland, hybrid constructed wetland, free surface constructed wetland and horizontal flow constructed wetland. Treatment options where biogas can be produced: anaerobic digestion, e.g. UASB reactors, biogas settlers or at large scale. Advanced (more high-tech options): activated sludge, MBRs, advanced oxidation processes, ozonation, activated carbon.

Reuse Possibilities:

- Reuse water for process washing

- Industrial fire protection

- In production line

- pH adjustment

Industries and local government facilities.

Tips for Business & Industry

The Future of Water Use in Industry. Global Ministerial Forum on Research for Health

This paper gives an overview about the water use in Industry of the past years and makes a projection of future uses. Furthermore, the paper gives advices how to save water in the future.

GROBICKI, A. (n.y): The Future of Water Use in Industry. Global Ministerial Forum on Research for Health. Geneva: World Health Organization URL [Accessed: 06.05.2019]Ecology of Estuaries: Anthropogenic Effects

Industrial Water Reuse and Wastewater Minimization

This document explains how to reuse water and wastewater in Industry.

MCYINTRE, J.P. (2006): Industrial Water Reuse and Wastewater Minimization. Trevose: GeWater URL [Accessed: 23.07.2010]Occupant Engagement–Where Design Meets Performance

Industrial Water Use

This document illustrates the water use in industry around the world.

SASI GROUP (2006): Industrial Water Use. Sheffield: SASI Group URL [Accessed: 06.05.2019]Freshwater use by sector at the beginning of the 2000s

Chapter 7: Evolution of Water Use

Sick Water? The central role of wastewater management in sustainable development

This book not only identifies the threats to human and ecological health that water pollution has and highlights the consequences of inaction, but also presents opportunities, where appropriate policy and management responses over the short and longer term can trigger employment, support livelihoods, boost public and ecosystem health and contribute to more intelligent water management.

CORCORAN, E. ; NELLEMANN, C. ; BAKER, E. ; BOS, R. ; OSBORN, D. ; SAVELLI, H. (2010): Sick Water? The central role of wastewater management in sustainable development. A Rapid Response Assessment. United Nations Environment Programme (UNEP), UN-HABITAT, GRID-Arendal URL [Accessed: 05.05.2010] PDFThe Future of Water Use in Industry. Global Ministerial Forum on Research for Health

This paper gives an overview about the water use in Industry of the past years and makes a projection of future uses. Furthermore, the paper gives advices how to save water in the future.

GROBICKI, A. (n.y): The Future of Water Use in Industry. Global Ministerial Forum on Research for Health. Geneva: World Health Organization URL [Accessed: 06.05.2019]Industrial Water Reuse and Wastewater Minimization

This document explains how to reuse water and wastewater in Industry.

MCYINTRE, J.P. (2006): Industrial Water Reuse and Wastewater Minimization. Trevose: GeWater URL [Accessed: 23.07.2010]Water Utilisation in African Beverage Industries: Current Practices and Prospects

This document explains how you can save water in beverage industry. It contains good strategies how to conserve water in different process steps.

UNEP (2007): Water Utilisation in African Beverage Industries: Current Practices and Prospects. Nairobi: UNEP, Division of Technology, Industry & Economics URL [Accessed: 06.05.2019]Water conservation in textile industry

This document explains how you can save water in textile industry. It contains good strategies how to conserve water in different process steps.

SHAIKH, M. A. (2009): Water conservation in textile industry. Karachi: SFDAC URL [Accessed: 09.08.2010]Water Efficiency Manual. North Carolina: Department of Environment and Natural Resources

This paper explains how to use water more efficiently in commercial, industrial and institutional facilities.

DEPARTMENT OF ENVIRONMENT AND NATURAL RESOURCES (2009): Water Efficiency Manual. North Carolina: Department of Environment and Natural Resources. URL [Accessed: 07.05.2019]Industrial Water Use

This document illustrates the water use in industry around the world.

SASI GROUP (2006): Industrial Water Use. Sheffield: SASI Group URL [Accessed: 06.05.2019]Urinals

A short article about the water consumption of urinals and how it can be reduced.

Occupant Engagement: Where Design Meets Performance

Building Green is a company providing accurate, unbiased, and timely information designed to help building-industry professionals and policy makers improve the environmental performance, and reduce the adverse impacts, of buildings.

World Business Council for Sustainable Development (WBCSD)

The World Business Council for Sustainable Development (WBCSD) is a CEO-led, global association of some 200 companies dealing exclusively with business and sustainable development. There is also a section on water.