Membrane Bioreactors (MBR) are treatment processes, which integrate a perm-selective or semi-permeable membrane with a biological process (JUDD 2011). It is the combination of a membrane process like microfiltration or ultrafiltration with a suspended growth bioreactor, and is now widely used for municipal and industrial wastewater treatment with plant sizes up to 80’000 population equivalents (BEDDOW 2010). Due to it being a very technical solution; it needs expert design and skilled workers. Furthermore it is a costly but efficient treatment possibility. With the MBR technology, it is possible to upgrade old wastewater plants.

| In | Out |

|---|---|

Faecal Sludge , Treated Water |

(Adapted from FITZGERALD 2008)

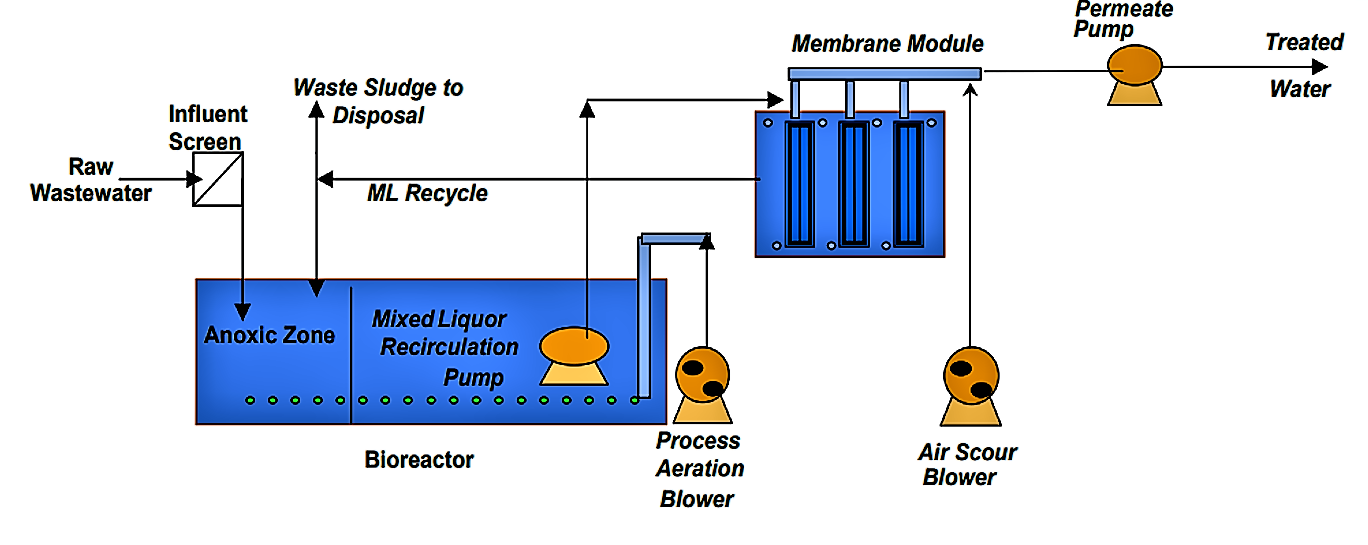

Membrane Bioreactors combine conventional biological treatment (e.g. activated sludge) processes with membrane filtration to provide an advanced level of organic and suspended solids removal. When designed accordingly, these systems can also provide an advanced level of nutrient removal. In an MBR system, the membranes are submerged in an aerated biological reactor. The membranes have porosities ranging from 0.035 microns to 0.4 microns (depending on the manufacturer), which is considered between micro and ultrafiltration.

This level of filtration allows for high quality effluent to be drawn through the membranes and eliminates the sedimentation and filtration processes typically used for wastewater treatment. Because the need for sedimentation is eliminated, the biological process can operate at a much higher mixed liquor concentration. This dramatically reduces the process tankage required and allows many existing plants to be upgraded without adding new tanks. To provide optimal aeration and scour around the membranes, the mixed liquor is typically kept in the 1.0-1.2% solids range, which is 4 times that of a conventional plant.

Membrane

(Adapted from RADJENOVIC et al. 2008)

During MBR wastewater treatment, solid–liquid separation is achieved by Microfiltration (MF) or Ultrafiltration (UF) membranes. A membrane is simply a two-dimensional material used to separate components of fluids usually on the basis of their relative size or electrical charge. The capability of a membrane to allow transport of only specific compounds is called semi-permeability (sometimes also permselective). This is a physical process, where separated components remain chemically unchanged. Components that pass through membrane pores are called permeate, while rejected ones form concentrate or retentate.

There are five types of membrane configuration which are currently in operation:

- Hollow fibre (HF)

- Spiral-wound

- Plate-and-frame (i.e. flat sheet (FS))

- Pleated filter cartridge

- Tubular

Read more about the several membrane possibilities in RADJENOVIC et al. (2008).

Pre-treatment

To avoid unwanted solids in the waste stream, which enters the membrane tank, fine screening is an essential pre-treatment step. This minimises an accumulation of solids and protects the membrane from damaging debris and particles, extends the membrane life, reduces operating costs and guarantees a higher sludge quality as well as a trouble free operation (GE 2011).

(Adapted from RADJENOVIC et al. 2008)

Although MBR capital and operational costs (membranes, oxygen utilisation, expert design, etc.) exceed the costs of conventional process, it seems that the upgrade of conventional process occurs even in cases when conventional treatment works well. This can be related to increase of water prices and the need for water reuse as well as with more stringent regulations on the effluent quality.

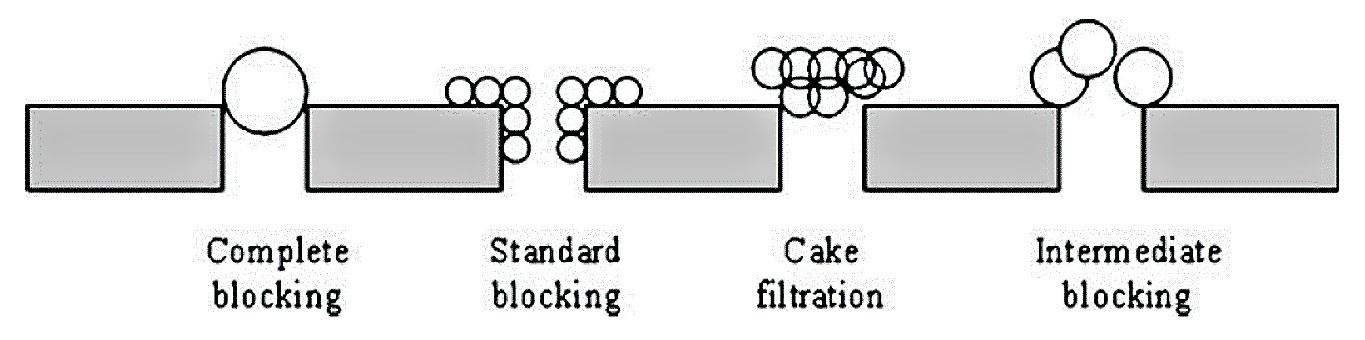

Most MBRs employ chemical maintenance cleaning on a weekly basis, which lasts 30–60 min, and recovery cleaning when filtration is no longer durable, which occurs once or twice a year. A deposit that cannot be removed by available methods of cleaning is called “irrecoverable fouling”. This fouling builds up over the years of operation and eventually determines the membrane life-time (RADJENOVIC et al. 2008). All O&M tasks have to be done by skilled workers.

Fouling

(Adapted from RADJENOVIC et al. 2008)

Modern systems (e.g. KUBOTA systems) are maintained with chemicals, i.e. it is not necessary to remove the membranes from the membrane tank. Organic fouling can be cleaned with as sodium hypochlorite and inorganic fouling with oxalic acid (KUBOTA 2010).

Fouling occurs as a consequence of interactions between the membrane and the mixed liquor, and is one of the principal limitations of the MBR process. Fouling of membranes in MBRs is a very complex phenomenon with diverse interlinkages among its causes, and it is very difficult to localise and define membrane fouling clearly. The main causes of membrane fouling are:

- Adsorption of macromolecular

- Growth of biofilms on the membrane surface

- Precipitation of inorganic matter

- Aging of the membrane

Operation and maintenance of MBR systems is generally carried out by skilled labourers, which should be sufficiently trained regarding any health risks. Sludge from the biological system should be dewatered (e.g. mechanical dewatering or drying bed) and incinerated with the ashes being stored in a controlled landfill.

| Working Principle | Membrane Bioreactors (MBRs) combine conventional biological treatment (e.g. activated sludge) processes with membrane filtration to provide an advanced level of organic and suspended solids removal. |

| Capacity/Adequacy | Applicable in conventional wastewater plants. |

| Performance | High |

| Costs | High capital and operational costs. |

| Self-help Compatibility | Low |

| O&M | Membranes need to be cleaned regularly. |

| Reliability | High if membranes are maintained correctly. |

| Main strength | Secondary clarifiers and tertiary filtration processes are eliminated, thereby reducing plant footprint. |

| Main weakness | High operation and capital costs (membranes). |

Membrane Bioreactor systems are widely used in municipal and industrial wastewater treatment plants. Furthermore, MBRs are also suitable for landfill leachate treatment. It is a high-tech system that needs expert design and professional operators.

Membrane Bioreactor

Membrane Bioreactors (MBR) for Municipal Wastewater Treatment – An Australian Perspective

This paper discusses the Membrane Bioreactor (MBR) process and its suitability for Australian water reuse applications. With the current focus on water reuse projects and the role they play in the water cycle, the search for cost competitive advanced wastewater treatment technologies has never before been so important.

CHAPMAN, S. LESLIE, G. LAW, I. (n.y): Membrane Bioreactors (MBR) for Municipal Wastewater Treatment – An Australian Perspective. Sidney: The University of New South Wales (UNSW) URL [Accessed: 03.06.2019]Membrane Bioreactors

Membrane Bioreactor (MBR) Design Considerations

KUBOTA Submerged Membrane Unit

This brochure of the MBR manufacturer KUBOTA gives an overview of how MBR systems work.

KUBOTA (2010): KUBOTA Submerged Membrane Unit. London: Kubota Membrane Europe URL [Accessed: 03.06.2019]Viability of Membrane Bioreactor Technology as an Advanced Pre-Treatment for Onsite Wastewater Treatment

This master thesis was a part of a research program at Colorado School of Mines. The objectives are threefold. Initially, the purposes were to increase the state of the knowledge using MBR in wastewater treatment and evaluate a pilot-scale MNR during start-up and steady state conditions, in respect of nutrient and organic compounds removal and overall system performance. A second objective was to evaluate the performance of the MBR during different stress conditions (power failure, high loading rate and high flux) in respect of nutrient and organic compounds removal and overall system performance. A third objective was to investigate permeate quality with respect of nutrients and organic compounds after infiltration through soil columns. The purpose was to assess if the effluent quality was suitable for direct discharge into the underlying groundwater or surface water.

LARSSON, E. PERSSON, J. (2004): Viability of Membrane Bioreactor Technology as an Advanced Pre-Treatment for Onsite Wastewater Treatment. (= Master Thesis ). Lulea: University of Technology URL [Accessed: 03.06.2019]Membrane Bioreactor (MBR) as an Advanced Wastewater Treatment Technology

In this chapter, the authors have covered several aspects of MBR, with an exhaustive overview of its operational and biological performance. Different configurations and hydraulics of MBR are presented, with attention given to the fouling phenomenon and strategies for reducing it. Also, the high quality of MBR effluent is discussed, whereas in comparison with CAS removals of organic matter, ammonia, phosphorus, solids, bacteria and viruses are significantly enhanced.

RADJENOVIC, J. MATOSIC, M. MIJATOVIC, I. PETROVIC, M. (2008): Membrane Bioreactor (MBR) as an Advanced Wastewater Treatment Technology. In: BARCELO, D. ; PETROVIC, M. (2008): Emerging Contaminants from Industrial and Municipal Waste. The Handbook of Environmental Chemistry. Berlin-Heidelberg: 37-101. URL [Accessed: 03.06.2019]Membrane Bioreactors (MBR) for Municipal Wastewater Treatment – An Australian Perspective

This paper discusses the Membrane Bioreactor (MBR) process and its suitability for Australian water reuse applications. With the current focus on water reuse projects and the role they play in the water cycle, the search for cost competitive advanced wastewater treatment technologies has never before been so important.

CHAPMAN, S. LESLIE, G. LAW, I. (n.y): Membrane Bioreactors (MBR) for Municipal Wastewater Treatment – An Australian Perspective. Sidney: The University of New South Wales (UNSW) URL [Accessed: 03.06.2019]Membrane Bioreactors

KUBOTA Submerged Membrane Unit

This brochure of the MBR manufacturer KUBOTA gives an overview of how MBR systems work.

KUBOTA (2010): KUBOTA Submerged Membrane Unit. London: Kubota Membrane Europe URL [Accessed: 03.06.2019]Viability of Membrane Bioreactor Technology as an Advanced Pre-Treatment for Onsite Wastewater Treatment

This master thesis was a part of a research program at Colorado School of Mines. The objectives are threefold. Initially, the purposes were to increase the state of the knowledge using MBR in wastewater treatment and evaluate a pilot-scale MNR during start-up and steady state conditions, in respect of nutrient and organic compounds removal and overall system performance. A second objective was to evaluate the performance of the MBR during different stress conditions (power failure, high loading rate and high flux) in respect of nutrient and organic compounds removal and overall system performance. A third objective was to investigate permeate quality with respect of nutrients and organic compounds after infiltration through soil columns. The purpose was to assess if the effluent quality was suitable for direct discharge into the underlying groundwater or surface water.

LARSSON, E. PERSSON, J. (2004): Viability of Membrane Bioreactor Technology as an Advanced Pre-Treatment for Onsite Wastewater Treatment. (= Master Thesis ). Lulea: University of Technology URL [Accessed: 03.06.2019]The Development of a Biofilm Membrane Bioreactor

Membrane Bioreactors (MBRs) are commonly understood as the combination of membrane filtration and biological treatment using activated sludge. Development of a biofilm-MBR has been investigated combining a moving-bed-biofilm reactor with a submerged membrane biomass separation reactor. Treatment efficiencies were found to be high with the production of a consistent high-quality effluent, irrespective of loading rates on the bioreactor or membrane reactor operating modes. Membrane performance (fouling) is a function of the biofilm reactor effluent quality and varies with loading rates (HRT). Sustainable operation was found to correlate to the fate of the submicron particle size fraction throughout the treatment process.

LEIKNES, T.O. ODEGARD, H. (2006): The Development of a Biofilm Membrane Bioreactor. Trondheim: Norwegian University of Science and Technology (NTNU) URL [Accessed: 03.06.2019]Membrane Bioreactor (MBR) as an Advanced Wastewater Treatment Technology

In this chapter, the authors have covered several aspects of MBR, with an exhaustive overview of its operational and biological performance. Different configurations and hydraulics of MBR are presented, with attention given to the fouling phenomenon and strategies for reducing it. Also, the high quality of MBR effluent is discussed, whereas in comparison with CAS removals of organic matter, ammonia, phosphorus, solids, bacteria and viruses are significantly enhanced.

RADJENOVIC, J. MATOSIC, M. MIJATOVIC, I. PETROVIC, M. (2008): Membrane Bioreactor (MBR) as an Advanced Wastewater Treatment Technology. In: BARCELO, D. ; PETROVIC, M. (2008): Emerging Contaminants from Industrial and Municipal Waste. The Handbook of Environmental Chemistry. Berlin-Heidelberg: 37-101. URL [Accessed: 03.06.2019]Membrane Bioreactor for Wastewater Treatment

This document gives an overview of how recent technical innovation and significant membrane cost reduction have pushed membrane bioreactors (MBRs) to become an established process option to treat wastewater.

UNSW (n.y): Membrane Bioreactor for Wastewater Treatment. Sidney: The University of New South Wales (UNSW). [Accessed: 08.12.2011] PDFSelected contributions from the 1st WATERBIOTECH conference, 9-11 October 2012, Cairo, Egypt

This issue publishes selected contributions from the 1st WATERBIOTECH conference. WATERBIOTECH („Biotechnology for Africa‘s sustainable water supply“) is a coordination and support action funded within the Africa call of the EU 7th Framework Programme.

ECOSAN CLUB (2013): Selected contributions from the 1st WATERBIOTECH conference, 9-11 October 2012, Cairo, Egypt. (= Sustainable Sanitation Pratice , 14 ). Vienna: Ecosan Club URL [Accessed: 29.01.2013]The Application of a Membrane Bioreactor for Wastewater Treatment

This study was intended to identify and test an appropriate and effective solution for the lack of adequate wastewater treatment in these communities. The MBR system, employing a Zenon ZW-10 ultrafiltration membrane, was designed and constructed at the University of Manitoba. It was installed and tested in two phases at the Opaskwayak Cree Nation Reserve in Northern Manitoba.

FREDERICKSON, K.C. (2005): The Application of a Membrane Bioreactor for Wastewater Treatment. (= Master Thesis ). Winnipeg: University of Manitoba URL [Accessed: 03.06.2019]Landfill Leachate Treatment

The application of membrane bioreactor technology for the treatment of landfill leachate is not new. This form of leachate treatment has been operating successfully within Germany and other European countries for nearly 15 years. From an environmental viewpoint, the application of MBR is perceived to be a superior process when compared to the alternative treatment techniques currently operating in the UK. This therefore begs the question, “Why have landfill operators in the UK not applied MBR technology for leachate treatment?”

ROBINSON, A.H. (2005): Landfill Leachate Treatment. Witney: Wehrle Environmental URL [Accessed: 01.03.2019]Greywater

This Sustainable Sanitation Practice (SSP) issue contains the following contributions: 1. Combined Greywater Reuse and Rainwater Harvesting in an Office Building - Austria, 2. Household Greywater Treatment for Peri-Urban Areas - Kenya, 3. Greywater Use in Peri-Urban Households - Uganda, 4. Greywater Treatment in Apartment Building - Austria, 5. Combined Greywater Treatment Using a Membrane Bioreactor.

MUELLEGGER, E. ; LANGEGRABER, G. ; LECHNER, M. (2009): Greywater . Treatment and Reuse. (= Sustainable Sanitation Practice , 1 ). Vienna: Ecosan Club URL [Accessed: 01.07.2013] PDFBioBarrier Membrane Bioreactor (MBR) Treatment System

This short youtube animation shows how a small scale MBR system works.

Installation of membrane bioreactor (MBR) filters at the Brightwater Treatment Plant

View the installation of Membrane Bioreactor (MBR) filters at the Brightwater Treatment Plant. This project uses Membrane Bioreactor (MBR) technology, which provides substantially better effluent quality than conventional secondary treatment. MBR effluent is suitable for irrigation of golf courses, playfields, and for industrial heating and cooling.

http://www.thembrsite.com/

The MBR website contains a description of the system, publications, links and an agenda for training courses.