A successful and efficient product manufacturing process depends on various aspects. Availability of resources, the location, quality management, process monitoring etc. Essential is an efficient production layout in accordance with the different process steps from planning to packaging of the product being produced. The production facilities factsheet helps a start-up or company to define and improve its manufacturing process by looking at it from a holistic perspective stipulating conceptual planning, macro-planning and micro-planning.

In this factsheet insights from TARA and Hydrologic provide the reader with hands-on information about how HWTS factories were set up and shares lessons learned. In the case study on production facilities, the case of Hydrologic and the Tunsai filter is discussed in more detail.

This factsheet aims to help a start-up to facilitate the planning of how to source and set up its production layout and the relative production site. Planning is important in order identify a feasible location, to prevent production inefficiencies and production drop-outs from the beginning and to deliver a sound product to its customers. By applying the different learnings from this example, your enterprise will be able to identify important steps to avoid fallacies in setting up its production process and the production layout respectively.

To set up a production, entrepreneurs have to think about:

- The suitable production process and its sub-processes which depend on the chosen technology(ies) that are produced (BENJAAFAR, HERAGU & IRANI, 2002).

- Hardware (e.g. machines) needed and the respective financial needs (see factsheet on financial analysis).

- Production facility and its location.

Note: It is important to look at the production process from a holistic perspective starting with a suitable location that serves not only production but integrates the whole supply chain and is feasible for distribution as well.

If the local circumstances are not favourable for setting-up a local production, third party sourcing or the set-up of a factory in a neighbouring country might be considered.

Household water treatment and storage (HWTS) products are often limited in their market reach. This is not only due to a lack of awareness among the population but often because the products are too expensive, not allowing enough margins to reach the very customers aimed at. From the start of a company onwards, efficiency is key and needs also to guide the set-up for a production unit.

To start setting up a production facility from scratch, identifying and planning the different steps within the production process is essential and influences the layout of a production. This handout provides hands-on insights of aspects to be considered when planning and setting up a HWTS production site.

This factsheet provides guidelines for start-ups, (social) entrepreneurs, NGOs and others that have already identified a feasible solution (see feasibility study) for delivering safe water at the point of use (PoU) and are in the preparation phase of setting up a production factory of a water treatment technology.

1. Conceptual planning, macro-planning and micro-planning of a production process and its layout

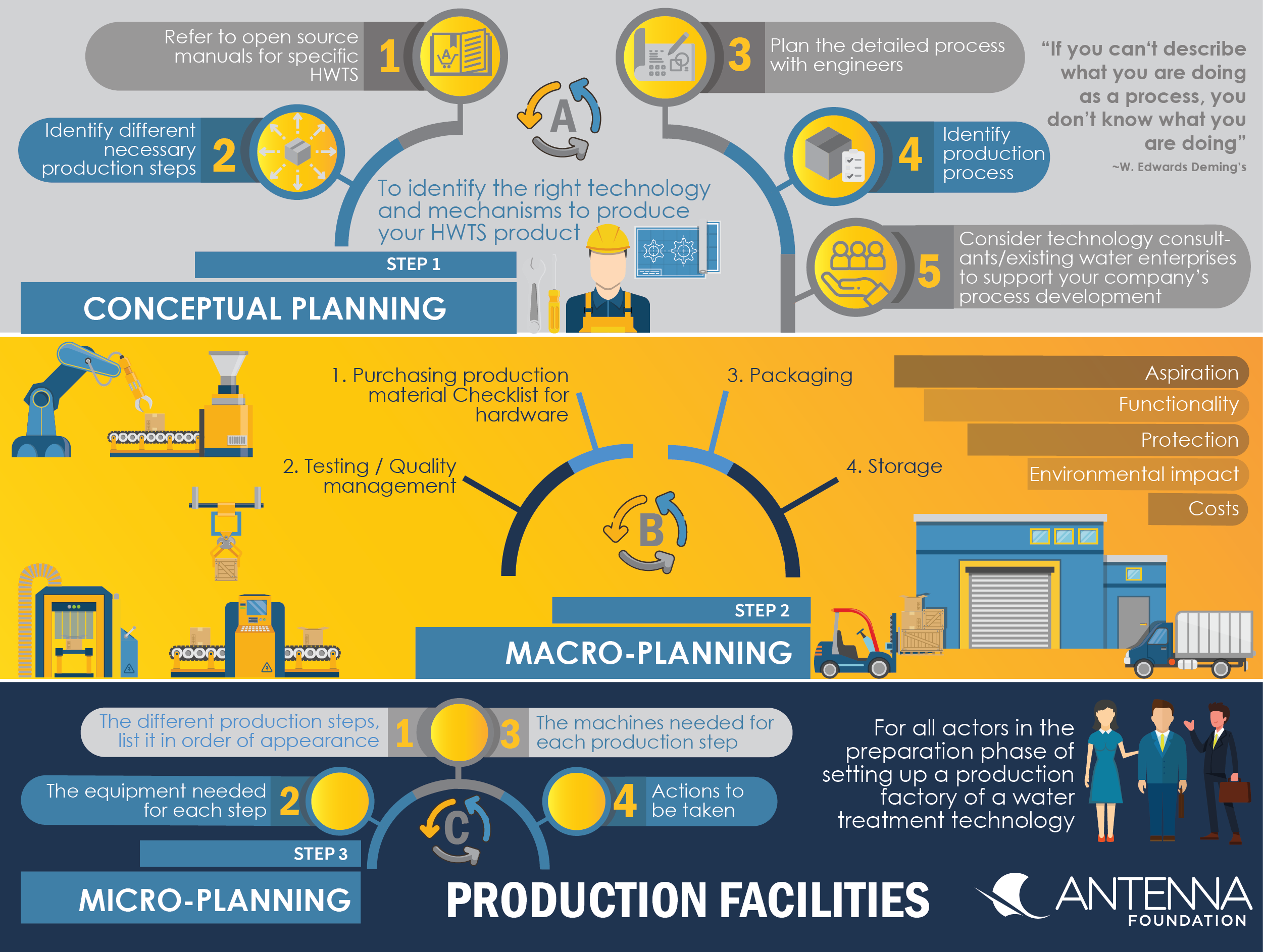

Considering W. Edwards Deming’s expression “if you can‘t describe what you are doing as a process, you don’t know what you are doing” it becomes apparent that a company needs to clearly know what its core activities are (Professor at Columbia University, lived 1900–1993). To identify the different steps within a company’s production process, a thorough planning is recommended as starting point. Planning can be differentiated in conceptual planning, macro-planning and micro-planning. Conceptual planning identifies the most suitable technology to produce a product, at the macro-planning level most suitable processes and factsheets are identified for production. Micro-planning determines then the detailed implementation of the identified process (USUI, 2016). The production planning influences the production layout of a company as such. General process steps are listed below:

Conceptual planning:

- To identify the right technology and mechanisms to produce your HWTS product:

- Refer to open source manuals for ceramic filters: Potters for peace, CAWST

- Identify the different production steps that are necessary

- Plan the detailed process together with engineers

- Identify the production process

- Consider technology consultants/ existing water enterprises to support your company’s process development

Macro-planning:

- Purchasing of production material:

Checklist for hardware: List machines you need and where to purchase them, if the machines required are not available in your context or are too expensive - be flexible and look for adequate alternative solutions that can be sourced locally.

- Testing / Quality management:

Quality control in the manufacturing process is also a key element in assuring customer confidence that the purchased HWTS system is providing safe water (MURCOTT, 2006) (see factsheet on quality control).

- Packaging:

Think about aspiration, functionality, protection, environmental impact and costs of the product as such:

Aspiration: Not only the product as such needs to meet the customer perception but the packaging should evenly reflect and carry value for the customer. The figure below serves as example: The nicely designed box from Hydrologic is widely kept for storing household items and so on. (See factsheets on social marketing and value proposition)

Functionality: The packaging can additionally serve as information platform explaining the use of the product or include additional information about the company, customer service etc. Keep in mind that customers might be illiterate – working with pictograms is a good idea and enhances functionality.

Protection: Your product packaging needs to protect the HWTS, keep in mind that delivery to rural areas might take time and needs to be feasible for these strains. A quality packaging safes costs as products do not easily break and augment the product perception and customer satisfaction. To assure protection, it is recommended to test different options in the field.

Environmental impact: Keep the aspect of environmental impact in mind. The product should match all criteria previously discussed, also considering the environment.

Costs: Keep the balance between qualitative and aspirational products under the restriction of costs. You can perform a willingness to pay analysis and market benchmark to set your packaging expenditure limits.

packaging of

AquaCleanDrops.

Source: Pakoswiss,

2016.

- Storing:

Think about the following questions:

- How should the storage look like (on company premises or externally)?

- What storage organisation and filing order is logical and efficient?

- How do you track the number of products produced and know how much is stockpiled and available (accounting)?

To internalize and (semi)-automate your warehouse activities there are a variety of software solutions available to support your warehouse management:

Warehousing and Inventory Management

Warehouse Management Implementation

Micro-planning:

- Production process:

To facilitate the description of your detailed production process, the process mapping method can be applied. Illustration below is the chlorine production scheme of Technology & Action for Rural Advancement (TARA) in India.

To clearly structure your production it is necessary to identify:

When the production process has been clearly mapped, the different necessary materials (resources, factsheets, spare parts etc.) for production should be looked for as well as the process set-up. For concrete implementation:

- List materials and figure out, where and under which conditions to purchase

- Is the supply predictable?

- Compare factsheet Third Party Sourcing

The procedure of setting up a production factory can be taken a step further by looking for a production facility. Use this checklist that helps identifying your facility location.

General notification:

The factor time is extremely crucial in setting up a production. Not only the construction of the facility but the planning, testing, quality control and honing of the production process as such are time consuming until a product can finally be delivered. Accordingly a sufficient amount of time has to be considered until the product launch. This fact implies monetary implications (compare finance & planning) (THARSUS, 2011; CHAMANIA, MEHTA AND SEHGAL, 2010). The above outlined issues should already be considered during the business planning and design of your business plan.

2. Third party sourcing – importance of protective contracts

Taking the decision to source from external manufacturers fully or partly brings the importance with it to identify the right partnership:

- Do you need a supplier with capabilities to develop a new product?

- Do you need low cost or high-quality products?

- What size should the company have?

These exhaustive checklists help you identifying the right partner:

Take into account that finding a partner takes time. Make sure you do not team up with the first potential company right away, but to undergo a due diligence in order to mitigate risk of a failing collaboration. It is advisable to have a back-up partner in mind or to source from different manufacturers simultaneously. When the right partner is identified you need to negotiate the conditions of collaboration. A contract serves a legally binding business relationship. Especially in fragile regulatory situations it is essential to have coherent and clearly regulated partnerships (SRINIVASAN, 2014).

The subsequent case study about the social enterprise Hydrologic provides insights on how the production process of ceramic filter manufacturing has been set up and shares lessons learned and recommendations.

Subscribe here to the new Sanitation and Water Entrepreneurship Pact (SWEP) newsletter. SWEP is a network of organizations joining hands to help entrepreneurs design and develop lasting water and sanitation businesses.

Next Generation Factory Layouts - Research Challenges and Recent Progress

Five Factors for Finding the Right Site

7 Tips for a Smooth Start to Manufacturing

The Real Costs of Setting Up A New Product Manufacturing Facility

Facilities Checklist

Lean Logistics-Understanding

Implementation Critical Factors and Challenges to Scale Up

Advancement of Intelligent Production Planning

9 Line Layout Mistakes to avoid

A modularised typology for flow design based on decoupling points – a holistic view on process industries and discrete manufacturing industries

Functionality of Product Packaging: Surveying Consumers’ Attitude Towards Selected Cosmetic Brands

This article discusses product packaging and consumer behavior and showcases findings in 4 case studies to learn from practically.

Published by Economics & Sociology under License: CC BY 3.0 IGO

GRUNDEY, D. (2010): Functionality of Product Packaging: Surveying Consumers’ Attitude Towards Selected Cosmetic Brands. In: Economics & Sociology: Volume 3 , 87-103. URL [Accessed: 23.07.2018] PDFOn Decoupling Points and Decoupling Zones

This paper outlines a framework for production and storage management based on content, represented by four key decision categories, and an overview of a process for applying the content.

Published by Taylor & Francis under License: CC BY 3.0 IGO.

WIKNER, J. (2014): On Decoupling Points and Decoupling Zones. In: Production & Manufacturing Research: Volume 2 , 167–215. . URL [Accessed: 23.07.2018] PDF