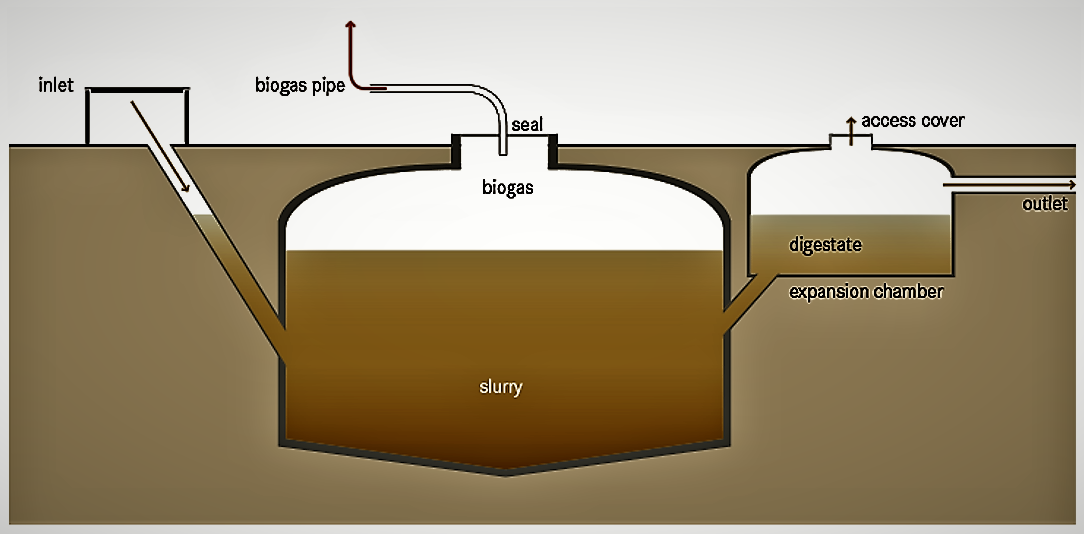

A biogas reactor or anaerobic digester is an anaerobic treatment technology that produces (a) a digested slurry (digestate) that can be used as a fertilizer and (b) biogas that can be used for energy. Biogas is a mix of methane, carbon dioxide and other trace gases which can be converted to heat, electricity or light.

| In | Out |

|---|---|

Blackwater, Faecal Sludge, Brownwater, Faeces, Excreta, Organic Solid Waste |

Biogas, Sludge, Compost/Biosolids |

A biogas reactor is an airtight chamber that facilitates the anaerobic degradation of blackwater, sludge, and/or biodegradable waste. It also facilitates the collection of the biogas produced in the fermentation processes in the reactor. The gas forms in the slurry and collects at the top of the chamber, mixing the slurry as it rises. The digestate is rich in organics and nutrients, almost odourless and pathogens are partly inactivated.

Biogas reactors can be brick-constructed domes or prefabricated tanks, installed above or below ground, depending on space, soil characteristics, available resources and the volume of waste generated. They can be built as fixed dome or floating dome digesters. In the fixed dome, the volume of the reactor is constant. As gas is generated it exerts a pressure and displaces the slurry upward into an expansion chamber. When the gas is removed, the slurry flows back into the reactor. The pressure can be used to transport the biogas through pipes. In a floating dome reactor, the dome rises and falls with the production and withdrawal of gas. Alternatively, it can expand (like a balloon). To minimize distribution losses, the reactors should be installed close to where the gas can be used.

The hydraulic retention time (HRT) in the reactor should be at least 15 days in hot climates and 25 days in temperate climates. For highly pathogenic inputs, a HRT of 60 days should be considered. Normally, biogas reactors are operated in the mesophilic temperature range of 30 to 38°C. A thermophilic temperature of 50 to 57°C would ensure the pathogens destruction, but can only be achieved by heating the reactor (although in practice, this is only found in industrialized countries).

Often, biogas reactors are directly connected to private or public toilets with an additional access point for organic materials. At the household level, reactors can be made out of plastic containers or bricks. Sizes can vary from 1,000 L for a single family up to 100,000 L for institutional or public toilet applications. Because the digestate production is continuous, there must be provisions made for its storage, use and/or transport away from the site.

The digestate is partially sanitized but still carries a risk of infection. Depending on its end-use, further treatment might be required. There are also dangers associated with the flammable gases that, if mismanaged, could be harmful to human health.

If the reactor is properly designed and built, repairs should be minimal. To start the reactor, it should be inoculated with anaerobic bacteria, e.g., by adding cow dung or septic tank sludge. Organic waste used as substrate should be shredded and mixed with water or digestate prior to feeding.

Gas equipment should be carefully and regularly cleaned so that corrosion and leaks are prevented. Grit and sand that have settled to the bottom should be removed. Depending on the design and the inputs, the reactor should be emptied once every 5 to 10 years.

This technology can be applied at the household level, in small neighbourhoods or for the stabilization of sludge at large wastewater treatment plants. The reactors are best used where regular feeding is possible.

Often, a biogas reactor is used as an alternative to a septic tank, since it offers a similar level of treatment, but with the added benefit of biogas. However, significant gas production cannot be achieved if blackwater is the only input. The highest levels of biogas production are obtained with concentrated substrates, which are rich in organic material, such as animal manure and organic market or household waste. It can be efficient to co-digest blackwater from a single household with manure if the latter is the main source of feedstock. Greywater should not be added as it substantially reduces the HRT. Wood material and straw are difficult to degrade and should be avoided in the substrate.

Biogas reactors are less appropriate for colder climates as the rate of organic matter conversion into biogas is very low below 15°C. Consequently, the HRT needs to be longer and the design volume substantially increased.

Biogas Technology - A Training Manual for Extension

This manual contains a complete set of training materials on various topics around the large-scale dissemination of domestic (agricultural) biogas systems, including a system approach to biogas technology, biogas programmes, reuse of slurry, subsidy and institutional financing, quality standards and monitoring and evaluation issues.

FAO (1996): Biogas Technology - A Training Manual for Extension. Support for Development of National Biogas Programme (FAO/TCP/NEP/4451-T) . Consolidated Management Services Nepal (P) Ltd. and Food and Agriculture Organization of the United Nations (FAO) URL [Accessed: 19.04.2010]Biogas Digest - Volume IV. Biogas - Country Reports

Technology Review of Biogas Sanitation

This document provides an overview and introduction on biogas sanitation (anaerobic digestion) for blackwater or for brown water, or excreta treatment for reuse in developing countries. The main technologies discussed are biogas settlers (BSs), biogas septic tanks, anaerobic baffled reactor (ABRs), anaerobic filter (AFs) and upflow anaerobic sludge blanket reactors (UASBs).

MANG, H.-P. LI, Z. (2010): Technology Review of Biogas Sanitation. (= Technology Review ). Eschborn: Deutsche Gesellschaft für Internationale Zusammenarbeit (GIZ) GmbH URL [Accessed: 26.05.2019]Anaerobic Digestion of Biowaste in Developing Countries

This book published by Eawag/Sandec compiles existing and recently generated knowledge on anaerobic digestion of urban biowaste at small and medium scale with special consideration given to the conditions prevailing in developing countries. Written for actors working in the waste and renewable energy sector, the book is divided into two parts: Part 1 focuses on practical information related to the anaerobic digestion supply chain (substrate-, process-, and product chain), and Part 2 presents selected case studies from around the world.

VOEGELI, Y. LOHRI, C.R. GALLARDO, A. DIENER, S. ZURBRUEGG, C. EAWAG (2014): Anaerobic Digestion of Biowaste in Developing Countries. Practical Information and Case Studies. Duebendorf: Swiss Federal Institute of Aquatic Science and Technology (Eawag) URL [Accessed: 28.05.2019]