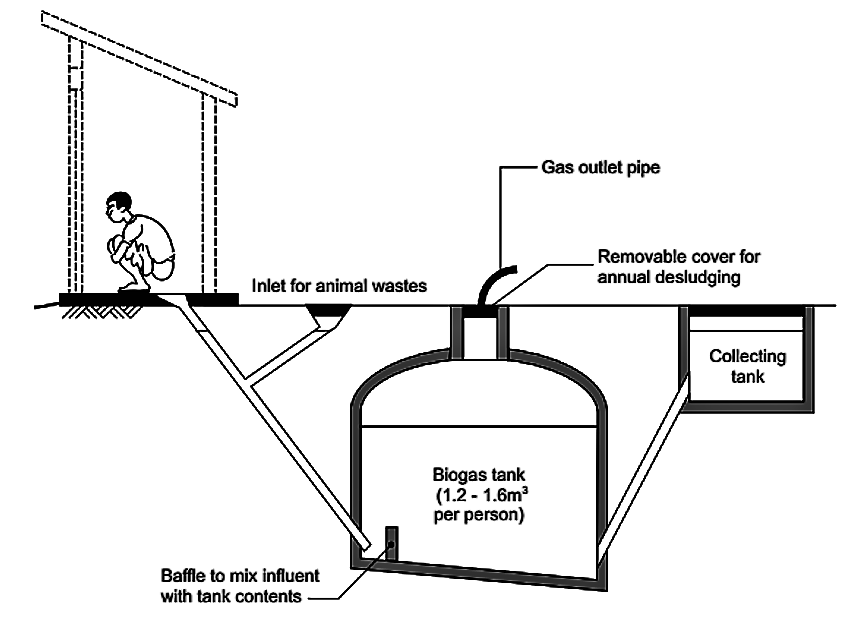

A small-scale biogas reactor or anaerobic digester is an anaerobic treatment technology that produces (a) a digested slurry (digestate) that can be used as a fertilizer and (b) biogas that can be used for energy. Biogas is a mix of methane, carbon dioxide and other trace gases which can be converted to heat, electricity or light. Small-scale biogas reactors are typically designed to produce biogas at the household or community level in rural areas. The airtight reactors are filled with animal manure from the farm. Kitchen and garden wastes can also be added and toilets can directly be linked to the reactor for co-treatment of excreta.

| In | Out |

|---|---|

Blackwater, Faecal Sludge, Brownwater, Faeces, Excreta, Organic Solid Waste |

Biogas, Sludge, Compost/Biosolids |

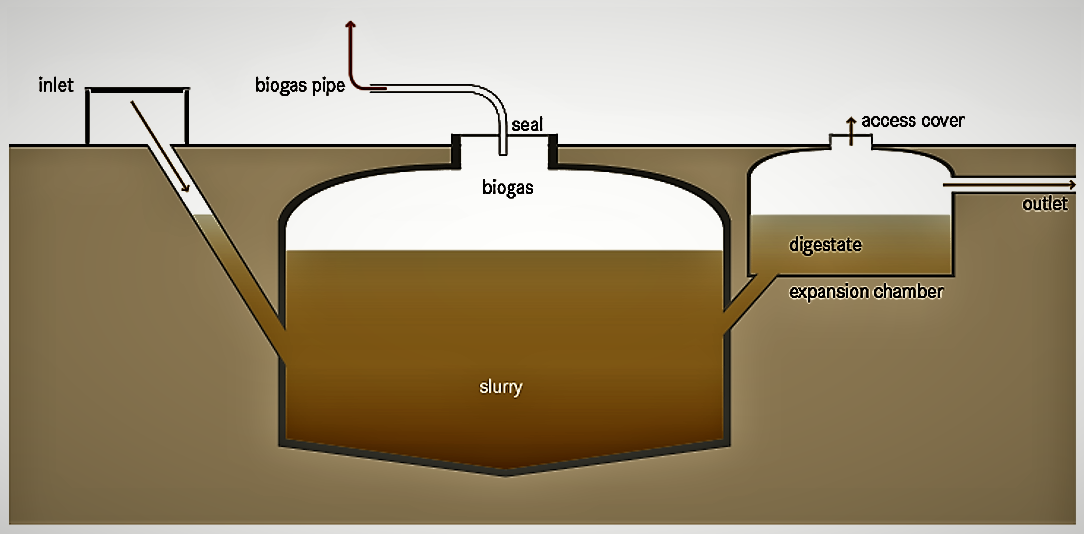

A biogas reactor is an airtight chamber that facilitates the anaerobic degradation of blackwater, sludge, and/or biodegradable waste (e.g. animal manure, kitchen and garden wastes) . It also facilitates the collection of the biogas , a mixture of methane (CH4) and carbon dioxide (CO2) produced in the fermentation processes in the reactor. The gas forms in the slurry and collects at the top of the chamber, mixing the slurry as it rises. The pressure exerted by the rising gas can be used to transport the gas to the collection vessel or directly to where it is going to be used. The digestate is rich in organics and nutrients, almost odourless and pathogens are partly inactivated.

Biogas reactors are often installed at household or community level in rural areas for the co-digestion of animal manure and toilet products.

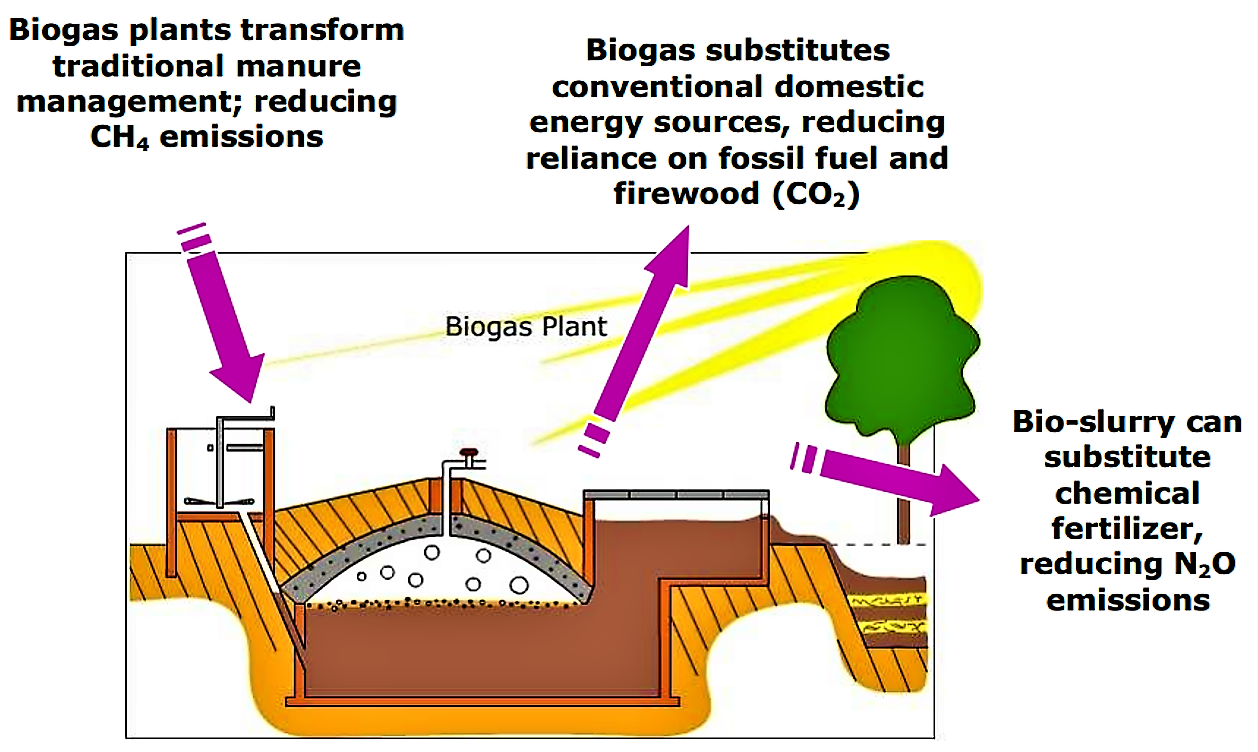

The produced gas can be recovered and used either directly for cooking and lighting or it can be transformed into heat in a gas heater system or into combined heat and power (CHP) in a cogeneration unit (MES et al. 2003; JENSSEN et al. 2004; WRAPAI 2009). Find more information on the use of biogas in the factsheets about direct use of biogas and small-scale conversion of biogas to electricity. The digestate (nutrient-rich sludge) can be used as fertilising soil amendment in agriculture.

Animal manure and kitchen waste contain a lot of organic matter and generally, the process produces enough biogas for the family to cover at least cooking requirements. Humans produce less excreta, which contains less material that can be converted to biogas than animal dung (e.g. cows). However, toilets, if available can directly be linked to the biogas plant where human faeces are digested together with the other wastes. This option provides a safe treatment of human excreta and thus improves the hygienic situation of the family. The availability of a renewable green energy source reduces the use of firewood for cooking and indoor air pollution. Thus biogas digesters have the potential to minimize health risks and environmental pollution by using human excreta as a resource for producing energy and fertiliser (GTZ 2007).

| Suitable digesting temperature | 20 to 35 °C |

| Retention time | 40 to 100 days |

| Biogas energy | 6kWh/m3 = 0.61 L diesel fuel |

| Biogas generation | 0.3 – 0.5 m3 gas/m3 digester volume per day |

| Human yields | 0.02 m3/person per day |

| Cow yields | 0.4 m3/Kg dung |

| Gas requirement for cooking | 0.3 to 0.9 m3/person per day |

| Gas requirement for one lamp | 0.1 to 0.15m3/h |

Biogas guideline data. Adapted from WERNER et al. (1989); ISAT/GTZ (1999), Vol. I; MANG (2005)

Biogas reactors can be brick-constructed domes or prefabricated tanks, installed above or below ground, depending on space, soil characteristics, available resources and the volume of waste generated. They can be built as fixed dome or floating dome digesters. In the fixed dome, the volume of the reactor is constant. As gas is generated it exerts a pressure and displaces the slurry upward into an expansion chamber. When the gas is removed, the slurry flows back into the reactor. The pressure can be used to transport the biogas through pipes. In a floating dome reactor, the dome rises and falls with the production and withdrawal of gas. Alternatively, it can expand (like a balloon). Rubber-balloon biogas plants, are the most simple and cheapest ones to construct. To minimize distribution losses, the reactors should be installed close to where the gas can be used. For more information on the different types of biogas reactors read the section “Types of Biogas Reactors”.

Anaerobic digestion is a biological process, which is carried out by a special mix of bacteria (see also the factsheet on anaerobic treatment of waste and wastewaters). When the reactors first are installed, it may take some time until the specific biogas producing bacterial community has installed. It can help to seed the reactor with anaerobic sludge form a septic tank or another anaerobic digester.

The hydraulic retention time (HRT) in the reactor should be at least 15 days in hot climates and 25 days in temperate climates. For highly pathogenic inputs, a HRT of 60 days should be considered. Normally, biogas reactors are operated in the mesophilic temperature range of 30 to 38°C. A thermophilic temperature of 50 to 57°C would ensure the pathogens destruction, but can only be achieved by heating the reactor (although in practice, this is only found in industrialized countries). If the temperature of the biomass is below 15°C, gas production will be so low that the biogas plant is no longer interesting from an economic point of view (ISAT/GTZ 1999, Vol. I). At higher temperature, not only methane production can be increased but also free ammonia, which can have an inhibitory effect on the digestion performance (ISAT/GTZ 1999, Vol. I).

| Digestion | Minimum | Optimum | Maximum | Retention time |

| 4 to 10 °C | 15 to 18 °C | 25 to 30 °C | >100 days | |

| Mesophilic | 10 to 20 °C | 28 to 33 °C | 35 to 45 °C | 30 to 60 days |

| 25 to 45 °C | 40 to 60 °C | 75 to 80 °C | 10 to 16 days |

Temperature ranges for anaerobic fermentation and respective required retention times. Source: WERNER et al. (1989) and MANG (2005)

Often, biogas reactors are directly connected to private or public toilets with an additional access point for organic materials. At the household level, reactors can be made out of plastic containers or bricks. Sizes can vary from 1,000 L for a single family up to 100,000 L for institutional or public toilet applications. Because the digestate production is continuous, there must be provisions made for its storage, use and/or transport away from the site. For more information on different small-scale biogas reactors see the section below.

The design size of the reactor depends on the HRT (depending on the temperature) and the volume of fermentation slurry (i.e. the feed material). The required volume is calculated by multiplying the daily amount of fermentation slurry by the HRT.

| Species | Daily manure, % of life-weight |

| Life-weight |

|

| Dung | TS |

|

| Cattle | 5 | 16 | 135-900 |

| Buffalo | 5 | 14 | 340-420 |

| Pigs | 2 | 16 | 30-75 |

| Sheep/goats | 3 | 30 | 30-100 |

| Chickens | 4.5 | 25 | 1.5-2 |

| Human | 1 | 20 | 50-80 |

Standard life-weight values of animal husbandry and average manure yields (dung and urine) as percentages of life-weight (adapted from WERNER et al. 1989)

To predict how much biogas will be produced with the wastes added to the reactor, one needs to know the chemical oxygen demand (COD) of the sludge or the biodegradability constant (total methane produced during a retention time of at least 50 days MES et al. 2003). Biogas, in general, can be obtained from any organic material (SASSE 1988), but the COD or biodegradability constant depends on the type of substrate. Animal dung has much higher methane producing potential than human excreta for example. The digestion of human faecal matter alone would not be economically interesting as the produced organic waste from a typical average family would not produced sufficient biogas to cover its needs. Considering a production of 0.12 Kg to 0.6 Kg faeces per day and person (JOENNSSEN 2004; YONGFU 1992) and 20 to 150 L Biogas per Kg (FAO 1996; SASSE 1996; GTZ 2009), the production of biogas would range from some few L to maximal 90 L (as a rule of thumb, 20 to 30 L Biogas per person per day is realistic). This is far less than the amount of biogas required to prepare the meal of one person, which is about 300 to 900 L biogas per day (ISAT/GTZ 1999, Vol. II).

Besides kitchen waste, garden wastes and plants can be added to the reactor to increase the biogas generation. Green plants are well suited for anaerobic digestion and their gas yields are high, usually above that of manure (WERNER et al. 1989). Feed material containing lignin, such as straw or wood resist anaerobic fermentation and should therefore not be used in biogas plants (WERNER et al. 1989) or at least be pre-composted and preferably chopped before digestion (SASSE 1988).

|

| Cattle | Buffalo | Pig | Chickens | Human | Source |

| L Biogas / Kg manure | 40 | 30 | 60 | 70 | 60 | MANG (2005) |

| L Biogas / Kg manure | 23-40 |

| 40-59 |

| 20-28 | UN (1984) in FAO (1996): |

| L Biogas / Kg manure |

|

|

|

| 40L | SASSE (1998) |

| L Biogas / Kg TS contained in faeces (30% of manure) |

|

|

|

| 430 L (at 35°C). 300 L (at 25°C) | GTZ (2009) |

Biogas production per category of animal and human faeces.

Small-scale biogas digesters generally follow a wet anaerobic digestion process with an optimal total solid (TS) content of 5 to 10% (SASSE 1988; NIJAGUNA 2002). The fluid properties of the slurry are important for the operation, as it is easier for the methane bacteria to come into contact with feed material accelerating the digestion process. Animals dung has generally higher TS content then required. To obtain an optimum TS content, substrates can be diluted (with greywater or toilet wastes for instance). Cow dung, for instance, which contains 18% of TS, is diluted with water in the ration of 1:1 (by weight) to obtain the optimum concentration of 9% TS (MAZUMDAR 1982; NIJAGUNA 2002).

The main design elements of small-scale biogas reactors are: an inlet, an airtight reactor chamber, a vessel for biogas collection (e.g. upper part of the reactor, floating drum, plastic balloons, see below), and an expansions chamber. Optionally, there are connections from the toilet(s) and a grinder for the kitchen and garden wastes. There are three general types of biogas reactors designs: rubber-balloon biogas plants, floating-drum plants and fixed-dome plants.

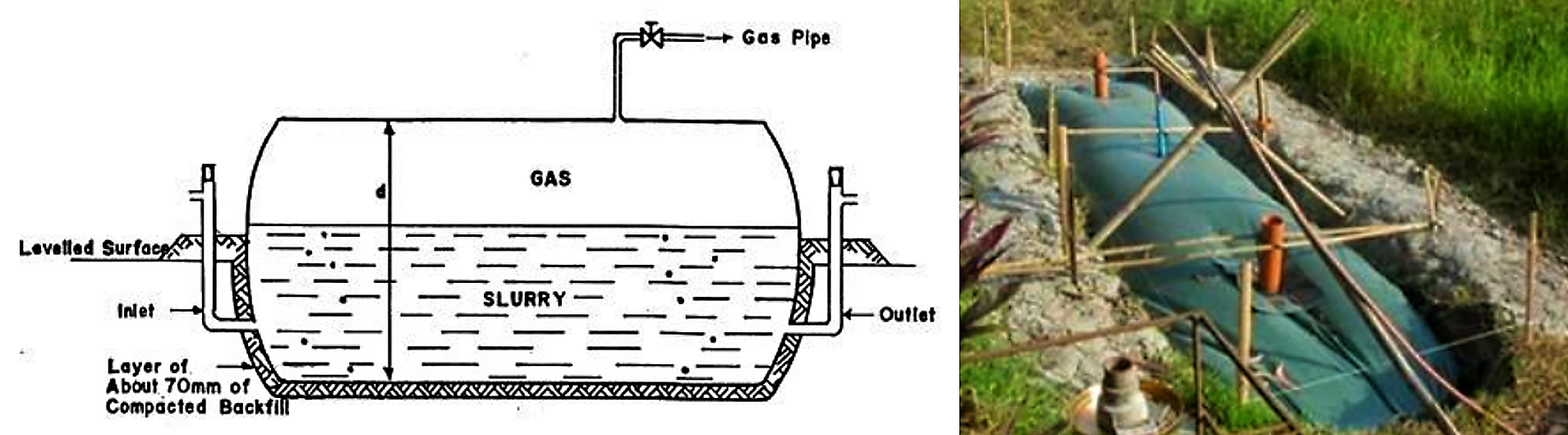

Rubber-balloon biogas plants

(adapted from ISAT/GTZ 1999, Vol. I)

Rubber-balloon biogas plants are the most simple and cheapest ones to construct. The balloon plant consists of a huge common plastic bag (e.g. PVC) in which the sludge settles on the bottom (there is no expansion chamber) and the gas is collected in the upper part from where it is withdrawn. The inlet and outlet are attached directly to the plastic skin of the balloon and there is now expansion chamber. To transport the gas from the balloon to where it will be used, the needed pressure is achieved through the elasticity of the balloon and can be enhanced by weights placed on the balloon. Besides its extremely low-cost and simplicity, this type of small-scale biogas digester has also the advantage of higher temperatures under sunny sky and its ease for cleaning and emptying. However, its life span can be relatively short as it is susceptible to damage and construction is so easy, that the creation of local employment is minimal. Another option, which is also easy and cheap to build is the construction of a fixed-dome reactor (see below), but to replace the fixed dome by plastic.

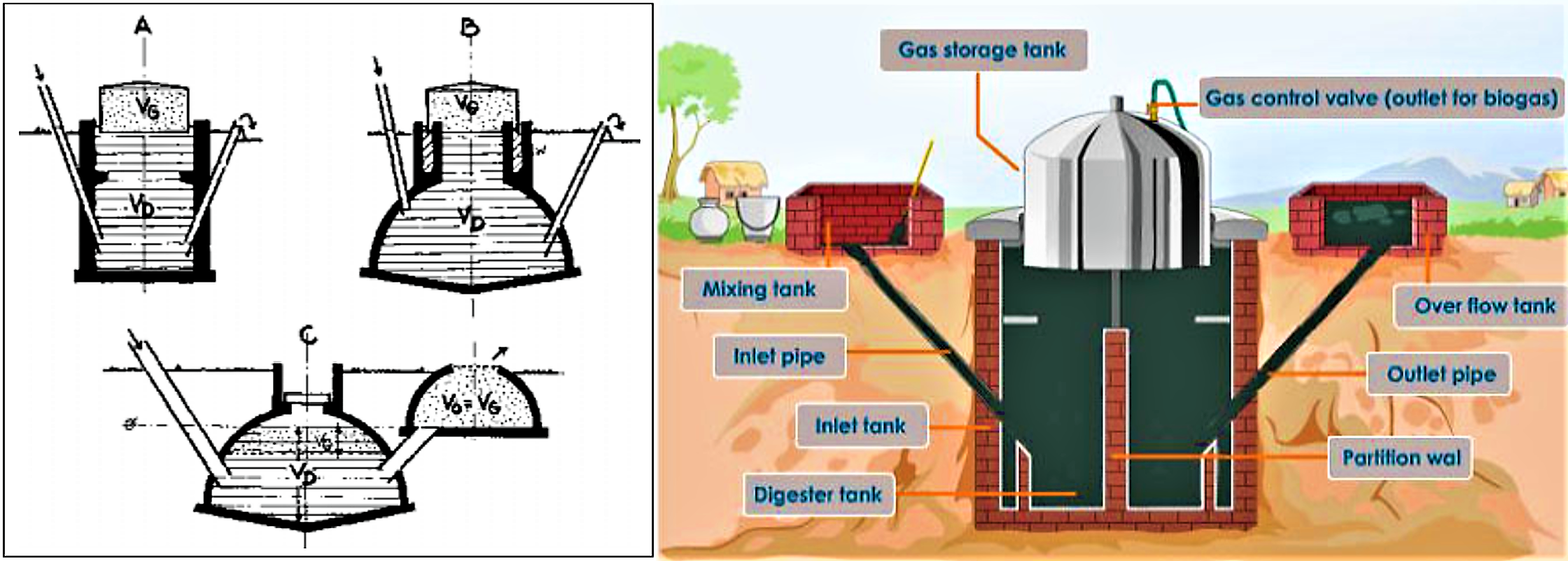

Fixed-dome reactors

(adapted from ISAT/GTZ 1999, Vol. I)

The fixed-dome plants consist of a digester with a fixed, non-movable gasholder, which sits on top of the digester. When gas production starts, the slurry is displaced into the compensation tank. Gas pressure increases with the volume of gas stored and the height difference between the slurry level in the digester and the slurry level in the compensation tank. Fixed-dome biogas plants have relatively low construction costs and do not contain rusting steel (as the floating-drum reactors). Thus, if they are well constructed, they have a long life span. The underground construction saves space and protects the digester from temperature changes. However, temperatures are generally relatively low. The construction provides opportunities for skilled local employment. However, problems of gas-tightness of the brickwork gasholder (or cracks) can cause heavy losses of biogas. Fixed-dome plants are, therefore, recommended only where experienced biogas technicians can supervise construction. The gas pressure fluctuates substantially depending on the volume of the stored gas.

Floating-drum reactors

(adapted from ISAT/GTZ 1999, Vol. I)

Floating-drum plants consist of an underground digester and a moving gasholder. The gasholder floats either directly on the fermentation slurry or in a water jacket of its own. The gas is collected in the gas drum, which rises or moves down, according to the amount of gas stored. The gas drum is prevented from tilting by a guiding frame. If the drum floats in a water jacket, it cannot get stuck, even in substrate with high solid content. Floating dome reactors have the advantage that the gas pressure remains constant as it depends on the weight of the gasholder. The construction is relatively easy and construction mistakes do not lead to major problems in functioning and gas yield. However, the material costs of the steel drum are very high and all the steel parts are susceptible to corrosion. Because of this, floating drum plants have a shorter life span than fixed-dome plants, and regular maintenance costs for the painting of the drum arise.

The digestate is partially sanitized but still carries a risk of infection. However, the state of hygienisation of the effluent slurry of biogas digesters strongly depends on the influent concentration in pathogenic microorganism, the retention time and the temperature. High temperatures and long retention times are more hygienic (SASSE 1988). If more than 55°C are achieved for one to a few days, inactivation can be considered as efficient (SCHOENNING & STENSTROEM 2004). Depending on its end-use, further treatment might be required. There are also dangers associated with the flammable gases that, if mismanaged, could be harmful to human health.

Anaerobic digestion only removes organics, and the main mineral material and almost all nutrients remain in the bottom sludge. Almost 100 % of the phosphorus and about 50 to 70 % of the nitrogen as ammonium is still found in the digested sludge (JOENSSEN et al 2004). Therefore, the secondary product compost from biogas reactors is a valuable resource for food production. Generally, in a well-functioning and designed biogas digester, the pathogen removal in the slurry is sufficient so the treated sludge can be reused for soil fertilisation. To increase the safety, it may be aerobically composted (or processed in a sludge drying or humification bed) before reuse.

Investment costs of anaerobic digesters are moderate and the potential of self-help is relatively high (even though planning requires skilled labour and expert design). Both biogas and fertilising sludge create value added, thus making biogas digesters interesting from an economic point of view.

If the reactor is properly designed and built, repairs should be minimal. To start the reactor, it should be inoculated with anaerobic bacteria, e.g., by adding cow dung or septic tank sludge. Biogas reactors need a start-up phase during which the microorganism responsible for anaerobic digestion instal and stabilise. Organic waste used as substrate should be shredded and mixed with water or digestate prior to feeding.

Gas equipment should be carefully and regularly cleaned so that corrosion and leaks are prevented. Grit and sand that have settled to the bottom should be removed. Depending on the design and the inputs, the reactor should be emptied once every 5 to 10 years. The reactors should also regularly be checked for foaming, scum formation or gas tightness (and rusting in the case of floating drum reactors using a steel drum). No skilled operator is required, but households should be trained to understand the system.

| Working principle | Animal manure is mixed with human wastes and crop residues in an airtight reactor, where it is decomposed in absence of oxygen and with a relatively high moisture content. Organic wastes are transformed into biogas, which can be reused for cooking, lightening or as another energy source. Nutrients (nitrogen and phosphorus) remain in the digested slurry which ca be used as a fertiliser in agriculture. |

| Capacity/adequacy | This type of reactor is generally constructed in rural areas where animal dung and space is available and the demand for biogas (as alternative energy) and fertiliser is high. But they can also be adapted to urban areas in the case of a high demand for biogas. |

| Performance | 80 to 85 % BOD; Relatively high pathogen removal; N and P remain in the sludge; HRT from one week up to several month depending on T |

| Costs | Low capital and low operating costs |

| Self-help compatibility | Design needs to be done by expert and construction should be supervised; operation staff needs to receive training to understand the functioning. Can be constructed with locally available material. |

| O&M | De-sludging should not really be required but cleaning (removal of stones and other indigestible material) may be useful; Checking for gas-tightness should be done regularly as well. |

| Reliability | Resistant to shock loading. Reliable if operated and maintained well. |

| Main strength | High removal of organic pollutants without any requirement for energy; Generation of biogas and fertiliser (compost). |

| Main weakness | Expert design and supervision of construction is required; The organic and solid content in the influent needs to be monitored. |

This technology can be applied at the household level, in small neighbourhoods or for the stabilization of sludge at large wastewater treatment plants. Biogas reactors provide energy for cooking, lighting and heating as well as fertilising sludge for soil improvement. In rural areas, they are often used for the digestion of animal manure, kitchen waste (and only optionally toilet wastes). The reactors are best used where regular feeding is possible see also anaerobic digestion in general .

Often, a biogas reactor is used as an alternative to a septic tank, since it offers a similar level of treatment, but with the added benefit of biogas. However, significant gas production cannot be achieved if blackwater is the only input. The highest levels of biogas production are obtained with concentrated substrates, which are rich in organic material, such as animal manure and organic market or household waste. It can be efficient to co-digest blackwater from a single household with manure if the latter is the main source of feedstock. Greywater should not be added as it substantially reduces the HRT. Wood material and straw are difficult to degrade and should be avoided in the substrate.

Biogas reactors are less appropriate for colder climates as the rate of organic matter conversion into biogas is very low below 15°C (WERNER et al. 1989) . Consequently, the HRT needs to be longer and the design volume substantially increased.

Biogas Technology - A Training Manual for Extension

This manual contains a complete set of training materials on various topics around the large-scale dissemination of domestic (agricultural) biogas systems, including a system approach to biogas technology, biogas programmes, reuse of slurry, subsidy and institutional financing, quality standards and monitoring and evaluation issues.

FAO (1996): Biogas Technology - A Training Manual for Extension. Support for Development of National Biogas Programme (FAO/TCP/NEP/4451-T) . Consolidated Management Services Nepal (P) Ltd. and Food and Agriculture Organization of the United Nations (FAO) URL [Accessed: 19.04.2010]MDG monitoring for urban water supply and sanitation. Catching up with reality in Sub-Saharan Africa

Biogas Basics

The information service on biogas technology has been developed and produced on the behalf of the GTZ project Information and Advisory Service on Appropriate Technology (ISAT). Volume I tells you all you need to get an overview on biogas sanitation systems, from history over process and operation parameters to social, political and cultural issues.

ISAT ; GTZ (1999): Biogas Basics. (= Biogas Digest , 1 ). Information and Advisory Services on Appropriate Technology (ISAT) and German Agency for Technical Cooperation GmbH (GTZ) URL [Accessed: 03.06.2019]Biogas - Application and Product Development

The information service on biogas technology has been developed and produced on the behalf of the GTZ project Information and Advisory Service on Appropriate Technology (ISAT). Volume II emphasises the design and operation of biogas plants.

ISAT ; GTZ (1999): Biogas - Application and Product Development. (= Biogas Digest , 2 ). Information and Advisory Services on Appropriate Technology (ISAT) and German Technical Cooperation (GTZ) GmbH URL [Accessed: 03.06.2019]Biogas - Costs and Benefits and Biogas – Programme Implementation

This information service on biogas technology has been developed and produced on the order of the GTZ project Information and Advisory Service on Appropriate Technology (ISAT). Volume III discusses the micro- and macro-economic viability of biogas sanitation systems.

ISAT ; GTZ (1999): Biogas - Costs and Benefits and Biogas – Programme Implementation. (= Biogas Digest , 3 ). Information and Advisory Services on Appropriate Technology (ISAT) and German Agency for Technical Cooperation GmbH (GmbH) URL [Accessed: 26.05.2019]Biogas - Country Reports

The information service on biogas technology has been developed and produced on the behalf of the GTZ project Information and Advisory Service on Appropriate Technology (ISAT). Volume IV summarises over 20 case studies from biogas sanitation as an appropriate technology in developing countries.

ISAT ; GTZ (1999): Biogas - Country Reports. (= Biogas Digest , 4 ). Information and Advisory Services on Appropriate Technology (ISAT) and German Agency for Technical Cooperation GmbH (GTZ). [Accessed: 19.04.2010] PDFGuidelines on the Use of Urine and Faeces in Crop Production

These guidelines provide a thorough background on the use of urine (and faeces) for agricultural purposes. Aspects discussed are requirements for plant growth, nutrients in excreta, hygiene aspects, and recommendations for cultivation. It provides detailed guidance on the use of urine for purposes.

JOENSSON, H. RICHERT, A. VINNERAAS, B. SALOMON, E. (2004): Guidelines on the Use of Urine and Faeces in Crop Production. (= EcoSanRes Publications Series , 2004 ). Stockholm: EcoSanRes URL [Accessed: 17.04.2012]Sustainable Wastewater Management in Urban Areas

A document about sustainable wastewater management in urban areas.

JENSSEN, P.D. GREATOREX, J.M. WARNER, W. S. (2004): Sustainable Wastewater Management in Urban Areas. (= Kapitel 4. Kurs WH33, Konzeptionen dezentralisierter Abwasserreinigung und Stoffstrommanagement ). Hannover: University of HannoverBiogas Sanitation Systems

This PDF-presentation gives a good introduction to biogas sanitation as a sustainable and ecological sanitation approach. Basic principles and main features are illustrated. Some design considerations are also addressed.

MANG, H. P. (2005): Biogas Sanitation Systems. (= Ecological sanitation course ). Beijing: Chinese Academy of Agricultural EngineeringTechnology Review of Biogas Sanitation

This document provides an overview and introduction on biogas sanitation (anaerobic digestion) for blackwater or for brown water, or excreta treatment for reuse in developing countries. The main technologies discussed are biogas settlers (BSs), biogas septic tanks, anaerobic baffled reactor (ABRs), anaerobic filter (AFs) and upflow anaerobic sludge blanket reactors (UASBs).

MANG, H.-P. LI, Z. (2010): Technology Review of Biogas Sanitation. (= Technology Review ). Eschborn: Deutsche Gesellschaft für Internationale Zusammenarbeit (GIZ) GmbH URL [Accessed: 26.05.2019]Biogas Handbook. Consolidation of Information

This handbook, even though it dates back to 1982, is quite comprehensive. It explains the theory of biogas productions, factors affecting plant designs, and operation of plants. Details of several popular biogas plant designs, construction and operation and maintenance are given. Designs of biogas utilisation devices and their operation requirements for use in lighting and cooking and as a fuel for prime movers are also included. The use of digested slurry as a source of organic fertilizer is discussed. Technical problems faced in the construction and operation of biogas plants and appliances are identified along with the causes and known solutions.

MAZUMDAR, A. (1982): Biogas Handbook. Consolidation of Information. Paris: United Nation Educational, Scientific and Cultural Organization (UNESCO)Chapter 4. Methane production by anaerobic digestion of wastewater and solid wastes

This chapter is part of a publication, commissioned by the Netherlands Agency for Energy and the Environment (Novem) on the status and perspectives of research and development in the field of high-tech biological production of methane and hydrogen. Chapter 4 gives a short but precise introduction the technological aspects of waste treatment by anaerobic digestion and the reuse of the produced biogas.

MES, T.Z.D. de STAMS, A.J.M. ZEEMAN, G. (2003): Chapter 4. Methane production by anaerobic digestion of wastewater and solid wastes. In: REITH, J.H. ; WIJFFELS, R.H. ; BARTEN, H. (2003): Biomethane and Biohydrogen. Status and perspectives of biological methane and hydrogen production. 58-94.Biogas Technology

Support Project to the Biogas Programme for the Animal Husbandry Sector in some Provinces of Vietnam

The Vietnamese and Netherlands Governments signed a Memorandum of Understanding for the implementation of a domestic biogas dissemination project in 10 provinces of Vietnam in January 2003. The project supports the agricultural sector in several provinces in Vietnam and uniquely joined Vietnams technical knowledge on fixed dome plant design and construction with Netherlands experience with large-scale dissemination of domestic biogas.

PBPO (2006): Support Project to the Biogas Programme for the Animal Husbandry Sector in some Provinces of Vietnam. (= BP I Final Report ). Hanoi: Provincial Biogas Project Office Hanoi URL [Accessed: 13.04.2010]Biogas Plants

This rather old document still gives a good overview on biogas technology. It is intended to help designers of a biogas plant to be able to distinguish between valid and invalid solutions.

SASSE, L. (1988): Biogas Plants. German Appropriate Technology Exchange (GATE) and German Agency for Technical Cooperation (GTZ) GmbH URL [Accessed: 15.05.2012]DEWATS

Exhaustive report on technological, operational and economic aspects of decentralised waste water treatment systems. Spreadsheet examples support the reader in designing and planning waste water treatment systems components.

SASSE, L. BORDA (1998): DEWATS. Decentralised Wastewater Treatment in Developing Countries. Bremen: Bremen Overseas Research and Development Association (BORDA) URL [Accessed: 03.06.2019]Guidelines on the Safe Use of Urine and Faeces in Ecological Sanitation Systems

These guidelines provide a thorough background on the safe use of urine and faeces for agricultural purposes. Aspects like the health risk associated we the use of human excreta in agriculture and how to limit them are discussed.

SCHOENNING, C. STENSTROEM, T.A. (2004): Guidelines on the Safe Use of Urine and Faeces in Ecological Sanitation Systems. (= EcoSanRes Publication Series ). Stockholm: Stockholm Environment Institute (SEI)Compendium of Sanitation Systems and Technologies. 2nd Revised Edition

This compendium gives a systematic overview on different sanitation systems and technologies and describes a wide range of available low-cost sanitation technologies.

TILLEY, E. ULRICH, L. LUETHI, C. REYMOND, P. ZURBRUEGG, C. (2014): Compendium of Sanitation Systems and Technologies. 2nd Revised Edition. Duebendorf, Switzerland: Swiss Federal Institute of Aquatic Science and Technology (Eawag) URL [Accessed: 28.07.2014] PDFAnaerobic Digestion of Biowaste in Developing Countries

This book published by Eawag/Sandec compiles existing and recently generated knowledge on anaerobic digestion of urban biowaste at small and medium scale with special consideration given to the conditions prevailing in developing countries. Written for actors working in the waste and renewable energy sector, the book is divided into two parts: Part 1 focuses on practical information related to the anaerobic digestion supply chain (substrate-, process-, and product chain), and Part 2 presents selected case studies from around the world.

VOEGELI, Y. LOHRI, C.R. GALLARDO, A. DIENER, S. ZURBRUEGG, C. EAWAG (2014): Anaerobic Digestion of Biowaste in Developing Countries. Practical Information and Case Studies. Duebendorf: Swiss Federal Institute of Aquatic Science and Technology (Eawag) URL [Accessed: 28.05.2019]Using Human Waste

This Technical Brief introduces the main issues one needs to consider to both control the process and optimize the benefits gained from using human waste, whilst minimizing the risks.

WELL (n.y): Using Human Waste. (= WELL Technical Briefs , 63 ). Loughborough: Water and Environmental health at London and Loughborough (WELL) URL [Accessed: 26.04.2010]Biogas Plants in Animal Husbandry

This guide addresses the planners and providers of stock-farming and agricultural-extension services in developing countries. It is intended to serve as a source of information on the potentials of and prerequisites for biogas technology: a decision-making and planning aid for the construction and dissemination of biogas plants: a book of reference for information on practical experience and detailed data.

WERNER, U. STOEHR, U. HEES., N. (1989): Biogas Plants in Animal Husbandry. German Appropriate Technology Exchange (GATE) and German Agency for Technical Cooperation (GTZ) GmbHDocument 8, Data Management Document, Appendix S 06 - Energy Research

This document provided by Waste Refinery Australia Project Association Inc. contains information on biogas, different types of cogeneration (CHP) and district heating. Additionally there are also facts and information on hydronics and gas flare.

WRAPAI (2009): Document 8, Data Management Document, Appendix S 06 - Energy Research. Australia: Waste Refinery Australia Project Association Incorporated (WRAPAI)The Biogas Technology in China

Compendium of Sanitation Systems and Technologies (Arabic)

This is the Arabic version of the Compendium of Sanitation Systems and Technologies. The Compendium gives a systematic overview on different sanitation systems and technologies and describes a wide range of available low-cost sanitation technologies.

TILLEY, E. ULRICH, L. LUETHI, C. REYMOND, P. SCHERTENLEIB, R. ZURBRUEGG, C. (2014): Compendium of Sanitation Systems and Technologies (Arabic). 2nd Revised Edition. Duebendorf, Switzerland: Swiss Federal Institute of Aquatic Science and Technology (Eawag) PDFAnaerobic Digestion of Biowaste in Developing Countries

This book published by Eawag/Sandec compiles existing and recently generated knowledge on anaerobic digestion of urban biowaste at small and medium scale with special consideration given to the conditions prevailing in developing countries. Written for actors working in the waste and renewable energy sector, the book is divided into two parts: Part 1 focuses on practical information related to the anaerobic digestion supply chain (substrate-, process-, and product chain), and Part 2 presents selected case studies from around the world.

VOEGELI, Y. LOHRI, C.R. GALLARDO, A. DIENER, S. ZURBRUEGG, C. EAWAG (2014): Anaerobic Digestion of Biowaste in Developing Countries. Practical Information and Case Studies. Duebendorf: Swiss Federal Institute of Aquatic Science and Technology (Eawag) URL [Accessed: 28.05.2019]Environmental Impact of Household Biogas Pants in India — Local and Global Perspective

In this study, the environmental impacts of biogas technology in India were studied when biogas as a cooking fuel substitutes bio-fuels (fuel wood, dung and crop residues) and fossil fuels (Kerosene and LPG)

ASIKAINEN, V. (2004): Environmental Impact of Household Biogas Pants in India — Local and Global Perspective. (= Master Thesis ). Jyvaskyla: University of JyvaskylaBiogas Production in Climates with long cold Winters

This study analyses the feasibility and potential production of biogas in countries with a cold climate, with emphasis on Romania, Kyrgyzstan, Georgia, Kazakhstan and Armenia. The results are compared with China, Nepal and Bolivia. The study also carefully reviews existing literature before suggesting the same technology for the colder target communities. It also contains recommendations on whether to use the plants on household or community level afterwards.

BALASUBRAMANIYAM, U. ZISENGWE, L.S. MERIGGI, N. BUYSMAN, E. (2008): Biogas Production in Climates with long cold Winters. Wageningen: Wageningen University URL [Accessed: 31.05.2019]Dairy Waste Anaerobic Digestion Handbook. Options for Recovering Beneficial Products from Dairy Manure

This manual provides an introduction to the anaerobic digestion of dairy manure. The operation and waste management practices of Idaho dairies, the anaerobic digestion and the anaerobic digestion processes suitable for dairy waste, the typical design applications for different types of dairies and finally the cost and benefits of the facilities are discussed.

BURKE, P.E. Dennis, A. (2001): Dairy Waste Anaerobic Digestion Handbook. Options for Recovering Beneficial Products from Dairy Manure. Olympia: Environmental Energy CompanyTechnologies demonstrated at Echo: Floating Drum Biogas Digester

This short document describes the concept and design of floating drum biogas digesters as developed at the Educational Concerns For Hunger Organization (ECHO).

DAHLMAN, J. FORST, C. (2002): Technologies demonstrated at Echo: Floating Drum Biogas Digester. (= An Echo Concept Paper ). North Fort Myers: Educational Concerns For Hunger Organization (ECHO) URL [Accessed: 12.08.2010]Report on the Feasibility Study for a Biogas Support Programme in the Republic of Rwanda

This report presents the findings of a study conducted by Ministry of Agriculture (MININFRA) and SNV to assess the feasibility to set-up and implement a national programme on domestic biogas in Rwanda.

DEKELVER, G. RUZIGANA, S. LAM, J. (2005): Report on the Feasibility Study for a Biogas Support Programme in the Republic of Rwanda. Netherlands Development Organisation (SNV) URL [Accessed: 09.04.2010]Technologies demonstrated at Echo: Horizontal Biogas Digester

This short document describes the concept and design of horizontal domestic biogas digesters as developed at the Educational Concerns For Hunger Organization (ECHO).

FORST, C. (2002): Technologies demonstrated at Echo: Horizontal Biogas Digester. (= An Echo Concept Paper ). North Fort Myers: Educational Concerns For Hunger Organization (ECHO) URL [Accessed: 20.04.2010]Emerging Biodigester Technology in Honduras: Biophysical Processes and Operation

Master thesis on biophysical and operational aspects of anaerobic bio-digesters in rural Honduras. Bio-digester processes, the operational practices for plastic balloon bio-digesters and a typology of successful bio-digester operation are developed.

GREEN, S. (2005): Emerging Biodigester Technology in Honduras: Biophysical Processes and Operation. (= Master Thesis ). Montana: University of MontanaDecentralised anaerobic digestion of market waste. Case study in Thiruvananthapuram, India

Decentralized anaerobic digestion is a promising technology to handle the large organic fraction of the municipal solid waste with the additional benefit of producing biogas as well as fertilizer. In this study a market level biogas plant in Thiruvananthapuram, South India and constructed by a NGO called BIOTECH is monitored and evaluated.

HEEB, F. (2009): Decentralised anaerobic digestion of market waste. Case study in Thiruvananthapuram, India. Duebendorf: Swiss Federal Institute of Aquatic Science and Technology (EAWAG) URL [Accessed: 31.05.2019]Biogas Basics

The information service on biogas technology has been developed and produced on the behalf of the GTZ project Information and Advisory Service on Appropriate Technology (ISAT). Volume I tells you all you need to get an overview on biogas sanitation systems, from history over process and operation parameters to social, political and cultural issues.

ISAT ; GTZ (1999): Biogas Basics. (= Biogas Digest , 1 ). Information and Advisory Services on Appropriate Technology (ISAT) and German Agency for Technical Cooperation GmbH (GTZ) URL [Accessed: 03.06.2019]Biogas - Application and Product Development

The information service on biogas technology has been developed and produced on the behalf of the GTZ project Information and Advisory Service on Appropriate Technology (ISAT). Volume II emphasises the design and operation of biogas plants.

ISAT ; GTZ (1999): Biogas - Application and Product Development. (= Biogas Digest , 2 ). Information and Advisory Services on Appropriate Technology (ISAT) and German Technical Cooperation (GTZ) GmbH URL [Accessed: 03.06.2019]Biogas - Costs and Benefits and Biogas – Programme Implementation

This information service on biogas technology has been developed and produced on the order of the GTZ project Information and Advisory Service on Appropriate Technology (ISAT). Volume III discusses the micro- and macro-economic viability of biogas sanitation systems.

ISAT ; GTZ (1999): Biogas - Costs and Benefits and Biogas – Programme Implementation. (= Biogas Digest , 3 ). Information and Advisory Services on Appropriate Technology (ISAT) and German Agency for Technical Cooperation GmbH (GmbH) URL [Accessed: 26.05.2019]Performance evaluation of a biogas stove for cooking in Nigeria

Journal article on a biogas digester, which was designed, constructed and its performance evaluated using a 3m3 continuous flow Indian type biogas plant at the Teaching and Research Farm, University of Agriculture, Makurdi, Nigeria. Various technical drafts and mathematical and chemical formulas are shown.

ITODO, I. N. ; AGYO, G. E. ; YUSUF, P. (2007): Performance evaluation of a biogas stove for cooking in Nigeria. In: Journal of Energy in Southern Africa: Volume 18 , 14-18. URL [Accessed: 09.04.2010]Anaerobic Reactors

Anaerobic Reactors is the forth volume in the series Biological Wastewater Treatment. The fundamentals of anaerobic treatment are presented in detail, including its applicability, microbiology, biochemistry and main reactor configurations. Two reactor types are analysed in more detail, namely anaerobic filters and especially UASB (upflow anaerobic sludge blanket) reactors. Particular attention is also devoted to the post-treatment of the effluents from the anaerobic reactors. The book presents in a clear and informative way the main concepts, working principles, expected removal efficiencies, design criteria, design examples, construction aspects and operational guidelines for anaerobic reactors.

LEMOS CHERNICHARO, C.A. de (2007): Anaerobic Reactors. (= Biological Wastewater Treatment Series , 4 ). London: International Water Association (IWA) Publishing. [Accessed: 01.11.2013]Chapter 4. Methane production by anaerobic digestion of wastewater and solid wastes

This chapter is part of a publication, commissioned by the Netherlands Agency for Energy and the Environment (Novem) on the status and perspectives of research and development in the field of high-tech biological production of methane and hydrogen. Chapter 4 gives a short but precise introduction the technological aspects of waste treatment by anaerobic digestion and the reuse of the produced biogas.

MES, T.Z.D. de STAMS, A.J.M. ZEEMAN, G. (2003): Chapter 4. Methane production by anaerobic digestion of wastewater and solid wastes. In: REITH, J.H. ; WIJFFELS, R.H. ; BARTEN, H. (2003): Biomethane and Biohydrogen. Status and perspectives of biological methane and hydrogen production. 58-94.Anaerobic Digestion of Biodegradable Solid Waste in Low- and Middle-Income Countries

Technology Review of Biogas Sanitation

This document provides an overview and introduction on biogas sanitation (anaerobic digestion) for blackwater or for brown water, or excreta treatment for reuse in developing countries. The main technologies discussed are biogas settlers (BSs), biogas septic tanks, anaerobic baffled reactor (ABRs), anaerobic filter (AFs) and upflow anaerobic sludge blanket reactors (UASBs).

MANG, H.-P. LI, Z. (2010): Technology Review of Biogas Sanitation. (= Technology Review ). Eschborn: Deutsche Gesellschaft für Internationale Zusammenarbeit (GIZ) GmbH URL [Accessed: 26.05.2019]Biogas Handbook. Consolidation of Information

This handbook, even though it dates back to 1982, is quite comprehensive. It explains the theory of biogas productions, factors affecting plant designs, and operation of plants. Details of several popular biogas plant designs, construction and operation and maintenance are given. Designs of biogas utilisation devices and their operation requirements for use in lighting and cooking and as a fuel for prime movers are also included. The use of digested slurry as a source of organic fertilizer is discussed. Technical problems faced in the construction and operation of biogas plants and appliances are identified along with the causes and known solutions.

MAZUMDAR, A. (1982): Biogas Handbook. Consolidation of Information. Paris: United Nation Educational, Scientific and Cultural Organization (UNESCO)Support Project to the Biogas Programme for the Animal Husbandry Sector in some Provinces of Vietnam

The Vietnamese and Netherlands Governments signed a Memorandum of Understanding for the implementation of a domestic biogas dissemination project in 10 provinces of Vietnam in January 2003. The project supports the agricultural sector in several provinces in Vietnam and uniquely joined Vietnams technical knowledge on fixed dome plant design and construction with Netherlands experience with large-scale dissemination of domestic biogas.

PBPO (2006): Support Project to the Biogas Programme for the Animal Husbandry Sector in some Provinces of Vietnam. (= BP I Final Report ). Hanoi: Provincial Biogas Project Office Hanoi URL [Accessed: 13.04.2010]Dissemination of improved stoves and biogas experiences in Burkina Faso

This PDF-presentation was presented a workshop in Ouagadougou entitled South-South cooperation in the field of Biomass energy: Challenge and opportunities. It illustrates how biogas technology was introduced along with cooking stoves and emphasizes technical and organisational lessons learnt.

SANOGO, O. (2008): Dissemination of improved stoves and biogas experiences in Burkina Faso. Institute de Recherche en Sciences Appliquées et Technologie (IRSAT) and Centre National de la Recherche Scientifique et Technologique (CNRST)Biogas Plants

This rather old document still gives a good overview on biogas technology. It is intended to help designers of a biogas plant to be able to distinguish between valid and invalid solutions.

SASSE, L. (1988): Biogas Plants. German Appropriate Technology Exchange (GATE) and German Agency for Technical Cooperation (GTZ) GmbH URL [Accessed: 15.05.2012]Improved Biogas Unit for Developing Countries

This booklet reflects seven years of experience of the Biogas Extension Service (BES) of CAMARTEC (Centre for Agricultural Mechanization and Rural Technology) in Arusha/Tanzania, which was carried out in cooperation with the GTZ from 1983 to 1986. It is meant as a teaching aid in agricultural colleges and as a reference book for professionals working in the field of rural biogas extension.

SASSE, L. (1991): Improved Biogas Unit for Developing Countries. German Appropriate Technology Exchange (GATE) and German Agency for Technical Cooperation (GTZ) GmbH URL [Accessed: 05.06.2019]DEWATS

Exhaustive report on technological, operational and economic aspects of decentralised waste water treatment systems. Spreadsheet examples support the reader in designing and planning waste water treatment systems components.

SASSE, L. BORDA (1998): DEWATS. Decentralised Wastewater Treatment in Developing Countries. Bremen: Bremen Overseas Research and Development Association (BORDA) URL [Accessed: 03.06.2019]Optimising simple biogas digesters for use in cold regions of developing countries

Livestock manures represent a valuable resource, which can produce clean renewable energy and valuable fertilizer. In many part os the world, livestock production is increasing. However, the amount of gas produced by small scale biogas plants is very limited. This paper researches how small-scale biogas plants can be adapted for use in cold regions in developing countries.

SOMMER, S.G. NORDDAHL, B. (2008): Optimising simple biogas digesters for use in cold regions of developing countries. Odense: University of Southern Denmark URL [Accessed: 29.07.2010]Biological Wastewater Treatment in Warm Climate Regions Volume 1

Biological Wastewater Treatment in Warm Climate Regions gives a state-of-the-art presentation of the science and technology of biological wastewater treatment, particularly domestic sewage. The book covers the main treatment processes used worldwide with wastewater treatment in warm climate regions given a particular emphasis where simple, affordable and sustainable solutions are required. The 55 chapters are divided into 7 parts over two volumes: Volume One: (1) Introduction to wastewater characteristics, treatment and disposal; (2) Basic principles of wastewater treatment; (3) Stabilisation ponds; (4) Anaerobic reactors; Volume Two (also available in the SSWM library): (5) Activated sludge; (6) Aerobic biofilm reactors; (7) Sludge treatment and disposal.

SPERLING, M. von LEMOS CHERNICHARO, C.A. de (2005): Biological Wastewater Treatment in Warm Climate Regions Volume 1. London: International Water Association (IWA) Publishing URL [Accessed: 26.05.2019]Links between Sanitation, Climate Change and Renewable Energies

This factsheet of Sustainable Sanitation Alliance describes the impact of greenhouse gases on climate change and focuses on the advantages of renewable energies. Therefore many different technologies like production of biogas or short-rotation-plantations are mentioned.

SUSANA (2009): Links between Sanitation, Climate Change and Renewable Energies. Eschborn. (= SuSanA fact sheet 09/2009 ). Sustainable Sanitation Alliance (SuSanA) URL [Accessed: 26.05.2019]Agricultural Engineering in Support of the Kyoto Protocol. The Clean Development Mechanism for Biogas Technology

This paper discusses the potential of the Clean Development Mechanisms (CDMs) for the commercialisation of the small- to large- scale Integrated Biogas System (IBS). IBS utilises a system approach for the efficient management and conversion of agro-industrial waste into clean biogas and organic fertilizer. The methane captured could either be used for electricity generation in large/medium commercial enterprises or used for cooking, lighting and heating hot water in small-scale community.

UN (n.y): Agricultural Engineering in Support of the Kyoto Protocol. The Clean Development Mechanism for Biogas Technology. United Nations (UN) Asian and Pacific Centre for Agricultural Engineering and Machinery (APCAEM)Feasibility Study for Developing Proposal under Clean Development Mechanism (CDM) for Claiming Carbon Credits for Leach Pit Toilets & Toilet Linked Biogas Plants

The promotion of leach pit toilets and toilet linked biogas plants, as well as solid and liquid waste management technologies implemented under the total sanitation campaign (TSC) in India reduces the emission of green house gases to the atmosphere. This report examines whether the TSC program qualifies for CDM benefits, which will greatly help in financing further sanitation related initiatives at national level.

WINROCK (2008): Feasibility Study for Developing Proposal under Clean Development Mechanism (CDM) for Claiming Carbon Credits for Leach Pit Toilets & Toilet Linked Biogas Plants. Winrock International IndiaBiogas Plants Based on Night Soil

The government of India started its biogas development project in 1981 as one of its programs designed to meet rural energy needs, especially for cooking. One of the solutions to the problem was the introduction of the concept of pay-and-use toilets championed by the Sulabh International Social Service Organisation, a non-profit voluntary organisation pioneering in the field of sanitation in India. The biogas generated is used largely for public lighting. Sulabh community toilets linked to biogas plants are generating energy and fertilizer, and some of them have attached health care facilities as well.

APEIS (2003): Biogas Plants Based on Night Soil. Asia-Pacific Environmental Innovation Strategies (APEIS), Research on Innovative and Strategic Policy Options (RISPO). (=Good Practices Inventory). Sulabh International and Agency for Non Conventional Energy and Rural Technology (ANERT)Pilot Integrate Waste Management Scheme for Small and Medium Scale Slaughterhouses

The Animal Products Development Centre, Bureau of Animal Industry (APDC-BAI), developed an integrated waste management scheme for small and medium scale slaughterhouses. Wastewater is treated in a DEWATS system developed together with BORDA. The system comprises a closed small-scale sewer system, an anaerobic digester, an anaerobic baffled reactor (ABR), an anaerobic filter (AF) and an aerobic planted filter as a final step to reduce odours.

APDC (n.y): Pilot Integrate Waste Management Scheme for Small and Medium Scale Slaughterhouses. Valenzuela City: Animal Products Development Centre, Bureau of Animal Industry (APDC-BAI) URL [Accessed: 20.04.2010]Domestic biogas for cooking and sanitation

The Biogas Sector Partnership (BSP) in Nepal managed the installation of over 124,000 domestic biogas plants in Nepal between 1992 and 2005. The plants use cattle manure to provide biogas for cooking and lighting. In addition, about 75% of the plants incorporate toilets.

ASHDEN (2005): Domestic biogas for cooking and sanitation. London: The Ashden Awards for Sustainable Energy URL [Accessed: 13.04.2010]Fuel, compost and sanitation from biogas in rural China

The Shaanxi Mothers' Environmental Protection Volunteer Association has installed 1,294 biogas plants in rural farming households in the Shaanxi Province of China since 1999. The plants produce biogas from pig and human waste.

ASHDEN (2006): Fuel, compost and sanitation from biogas in rural China. London: The Ashden Awards for Sustainable Energy URL [Accessed: 13.04.2010]Clean cooking and income generation from biogas plants in Karnataka

SKG Sangha (SKG S) is a non-profit organisation that supplies biogas plants to households in rural areas of South India. The ‘Deenbandu’ design plants are built on-site by local masons and labourers trained by SKGS, with very high quality standards. Plants produce biogas by digesting cow dung, replacing all the fuel wood used for cooking.

ASHDEN (2007): Clean cooking and income generation from biogas plants in Karnataka. London: The Ashden Awards for Sustainable Energy URL [Accessed: 14.03.2010]Decentralized Wastewater Treatment System - DEWATS

The wastewater from Manjuyod’s public market is treated in a decentralized system (DEWATS) composed of four different components: a settling tank; a anaerobic baffled reactor which reduces the BOD/COD content from 20% to 85%; a planted gravel filter; and finally a polishing pond.

BORDA (2008): Decentralized Wastewater Treatment System - DEWATS. Manjuyod Public Market. (= Sustainable Sanitation – Project Data Sheet ). Bremen: Bremen Overseas Research and Development Association (BORDA) URL [Accessed: 26.03.2010]Evaluation of Biogas Sanitation Systems in Nepalese Prisons

Biogas - Country Reports

The information service on biogas technology has been developed and produced on the behalf of the GTZ project Information and Advisory Service on Appropriate Technology (ISAT). Volume IV summarises over 20 case studies from biogas sanitation as an appropriate technology in developing countries.

ISAT ; GTZ (1999): Biogas - Country Reports. (= Biogas Digest , 4 ). Information and Advisory Services on Appropriate Technology (ISAT) and German Agency for Technical Cooperation GmbH (GTZ). [Accessed: 19.04.2010] PDFRecycling and reuse of human excreta from public toilets through biogas generation to improve sanitation, community health and environment

This paper has been written by the Director General Sulabh International Academy of Environmental Sanitation, which is well known for the installations of over 100 biogas linked public toilets in India. It gives an overview on the Sulabh approach and deals with many issues in brief way, including technical, social and economical aspects.

JHA, P.K. (n.y): Recycling and reuse of human excreta from public toilets through biogas generation to improve sanitation, community health and environment. New Delhi: Sulabh International Academy of Environmental Sanitation URL [Accessed: 12.08.2010]Empowering rural poor Women by Enhancing income through Biogas Plant by INSEDA and WAFD in Bharatapur, India

INSEDA (Integrated Sustainable Energy and Ecological Development Association) in partnership with WAFD (Women’s Action For Development) is implementing a new household biogas design to empower women in the villages of the Bharatpur district, Rajasthan (India) since 2002. This design is based on the principle of fixed-dome reactors but is built only with materials available locally in rural areas.

MYLES, R. (n.y): Empowering rural poor Women by Enhancing income through Biogas Plant by INSEDA and WAFD in Bharatapur, India. New Delhi: Integrated Sustainable Energy and Ecological Development Association (INSEDA) URL [Accessed: 12.08.2010]Ecological Sanitation in Uganda

This document presents a range of different projects implemented in Uganda around ecological sanitation, such as school sanitation, biogas and sludge treatmemt. These documented cases have been compiled in completion of a 15 months Ecological Sanitation Research Project implemented by Network for Water and Sanitation (NETWAS) Uganda as the ecosanres Uganda Knowledge Node with support from the Stockholm Environment Institute (SEI).

NETWAS EcoSanRes SEI (2011): Ecological Sanitation in Uganda. Inspirational Success Stories from the Field. Kampala: NETWAS Uganda URL [Accessed: 29.08.2011]Feasibility of a national programme on domestic biogas in Bangladesh

This report presents the findings of a study conducted by the Netherlands Development Organisation (SNV) to assess the feasibility of setting up and implementing a national programme on domestic biogas in Bangladesh.

NES, W.J. van BOERS, W. UL-ISLAM, K. (2005): Feasibility of a national programme on domestic biogas in Bangladesh. (= Final report ). Netherlands Development Organisation (SNV) URL [Accessed: 23.04.2010]Less hardship for women

Organic Farming with Slurry

Rural biogas plants not only produce a renewable energy source, but also valuable slurry, which can be, used as organic fertilizer for crop production.

NEWAR, N. (n.y): Organic Farming with Slurry. (= Success Stories from the Biogas Sector Partnership - Nepal ). Biogas Sector Partnership (BSP) URL [Accessed: 26.04.2010]Making Economic Sense

Individual Household Toilet Linked Biogas Plants. A Success Story in Salem District

The Salem is a hilly surrounded District in Tamil Nadu State with a tropical climate and temperatures within 35 to 40°C (thus perfectly suited for biogas plant). Ramu owns a toilet linked biogas plant and the improvement of his family’s socio-economic circumstances has had an enormous impact on local thinking. Now the local inhabitants of that area realise the importance of hygiene and the ecological and environmental values, and the demand for toilet-linked biogas plants is increasing steeply.

RAJAM, G. (n.y): Individual Household Toilet Linked Biogas Plants. A Success Story in Salem District. New Delhi: Ministry of Rural Development URL [Accessed: 25.04.2010]A biogas plant for the digestion of fresh undiluted cattle dung

This article describes how the popular fixed-dome type family size biogas plant has been successfully modified to allow use of fresh undiluted cattle dung as substrate. A large number of family-size biogas plants installed in the countryside in India use cattle dung diluted with an equal quantity of water as substrate. The biogas plant described below requires very little or no water for mixing with the cattle dung, and generates about 50% more biogas.

SHYAM, M. (2001): A biogas plant for the digestion of fresh undiluted cattle dung. In: Boiling Point: Volume 47 , 33-35.Technical and biological Performance of the ARTI Compact Biogas Plant for Kitchen Waste - Case Study from Tanzania

With the growing problem of municipal solid waste and the demand for an alternative energy source regarding rising petrol prices, anaerobic digestion technology has also been extended to organic solid wastes instead of animal dung and faecal wastes. This paper evaluates the suitability of a small-scale biogas system as a decentralised treatment option for the organic fraction of market and household solid waste in Dar el Salaam, Tanzania.

VOEGELI, Y. ; LOHRI, C. ; KASSENGA, G. ; BAIER, U. ; ZURBRUEGG, C. (2009): Technical and biological Performance of the ARTI Compact Biogas Plant for Kitchen Waste - Case Study from Tanzania. In: Proceedings Sardinia 2009, Twelfth International Waste Management and Landfill Symposium S. Margherita di Pula, Cagliari, Italy; 5 - 9 October 2009. Environmental Sanitary Engineering Centre (CISA): URL [Accessed: 06.06.2019]Integrated systems on biogas production, non-polluted agricultural production and sanitation in rural China

This paper introduces three typical biogas systems which regard anaerobic fermentation of human and animal “wastes” as a key technology, and which link sanitation and biogas production with agricultural use of digested effluents.

XIANGJUN, Y. ; WANG, H. (2003): Integrated systems on biogas production, non-polluted agricultural production and sanitation in rural China. In: Proceedings of the 2nd international symposium, F. 7th-11th April, Luebeck, Germany: , 601-606.Biogas Systems

During the last years a number of biogas systems have been installed as part of sanitation systems. Issue 9 of Sustainable Sanitation Practice (SSP) on „Biogas systems“ shows successful examples. The first paper presents results from a study in Kerala, India, for digesters on a household level. The second paper shows the results of a long-term implementation program for biogas systems in Lesotho. The third paper presents first results of a digester constructed in a small village in Morocco.

MUELLEGGER, E. ; LANGERGRABER, G. ; LECHNER, M. (2011): Biogas Systems. (= Sustainable Sanitation Practice , 9 ). EcoSan Club URL [Accessed: 24.10.2011]Public toilet with biogas plant and water kiosk, Naivasha, Kenya

A sanitation unit (toilet, hand wash basins, a urinal and showers) and a water kiosk were constructed for a public bus park (design sale was 1000 visitors per day). This projects aimed to improve living conditions of the residents and travellers by providing environmentally-friendly sanitation solutions with a focus on the reuse of the human waste as a resource and to find a business-oriented solution that creates economic incentives for the water sector institutions to invest in sanitation and to generate income for private operators.

RIECK, C. ONYANGO, P. (2010): Public toilet with biogas plant and water kiosk, Naivasha, Kenya. (= SuSanA - Case Studies ). Eschborn: Sustainable Sanitation Alliance (SuSanA) URL [Accessed: 12.12.2012]Decentralized Wastewater Management at Adarsh College, Badalapur, Maharashtra, India

This case study reports the development of an ecologically sound sanitation concept at the Adarsh Bidyaprasarak Sanstha's College of Arts & Commerce. In comprises separate urine collection and a DEWATS system for the treatment of black- and greywater consisting of a biogas settler, an anaerobic baffled reactor and an anaerobic filter, a horizontal flow constructed wetland and a polishing pond.

ZIMMERMANN, N. WAFLER, M. (2009): Decentralized Wastewater Management at Adarsh College, Badalapur, Maharashtra, India. (= SuSanA - Case Studies ). Eschborn: Sanitation Alliance (SuSanA) URL [Accessed: 25.04.2010]Technical Drawing: Cross-Section of a Fixed Dome Biogas Plant (12 m3)

Technical Drawing: Cross-Section of a Fixed Dome Biogas Plant (124 m3)

Technical drawing showing a design of a fixed dome biogas plant with a volume of 124 m3 and a gas storage capacity of 15 m3.

AKUT (2008): Technical Drawing: Cross-Section of a Fixed Dome Biogas Plant (124 m3). Berlin: AKUT Partner URL [Accessed: 12.05.2014]Deenbandhu Model 2000 Biogas Plant

Design manual for a fixed-dome biogas digester plant developed in India.

AFPRO (2005): Deenbandhu Model 2000 Biogas Plant. Valenzuela City: Action For Food Production (AFPRO) URL [Accessed: 20.04.2010]Design of Biogas Plant

Design manual for an agricultural cattle-fed domestic biogas digester including volume calculation of the digester and the hydraulic chamber and hydraulic retention times. Compiled by the Biogas Training Centre (BRC) Chendu, Sichuan (China).

BRC (n.y): Design of Biogas Plant. Sichuan (China): Biogas Training Centre (BRC) ChenduBiogas Technology - A Training Manual for Extension

This manual contains a complete set of training materials on various topics around the large-scale dissemination of domestic (agricultural) biogas systems, including a system approach to biogas technology, biogas programmes, reuse of slurry, subsidy and institutional financing, quality standards and monitoring and evaluation issues.

FAO (1996): Biogas Technology - A Training Manual for Extension. Support for Development of National Biogas Programme (FAO/TCP/NEP/4451-T) . Consolidated Management Services Nepal (P) Ltd. and Food and Agriculture Organization of the United Nations (FAO) URL [Accessed: 19.04.2010]Evaluation of Biogas Sanitation Systems in Nepalese Prisons. Summary Presentation of Evaluation Results

10 to 20m3 biogas digesters were installed in three different prisons and fed with human excreta and kitchen waste. Pathogen requirement were only partially fulfilled and slurry application as fertilizer needs further investigation and promotion.

EAWAG ; SANDEC (2009): Evaluation of Biogas Sanitation Systems in Nepalese Prisons. Summary Presentation of Evaluation Results. Duebendorf: Swiss Federal Institute of Aquatic Science (EAWAG), Department of Water and Sanitation in Developing Countries (SANDEC). [Accessed: 27.04.2010] PDFGas Bio-digester Information and Construction Manual For Rural Families

Biogas Basics

The information service on biogas technology has been developed and produced on the behalf of the GTZ project Information and Advisory Service on Appropriate Technology (ISAT). Volume I tells you all you need to get an overview on biogas sanitation systems, from history over process and operation parameters to social, political and cultural issues.

ISAT ; GTZ (1999): Biogas Basics. (= Biogas Digest , 1 ). Information and Advisory Services on Appropriate Technology (ISAT) and German Agency for Technical Cooperation GmbH (GTZ) URL [Accessed: 03.06.2019]Biogas - Application and Product Development

The information service on biogas technology has been developed and produced on the behalf of the GTZ project Information and Advisory Service on Appropriate Technology (ISAT). Volume II emphasises the design and operation of biogas plants.

ISAT ; GTZ (1999): Biogas - Application and Product Development. (= Biogas Digest , 2 ). Information and Advisory Services on Appropriate Technology (ISAT) and German Technical Cooperation (GTZ) GmbH URL [Accessed: 03.06.2019]Biogas - Costs and Benefits and Biogas – Programme Implementation

This information service on biogas technology has been developed and produced on the order of the GTZ project Information and Advisory Service on Appropriate Technology (ISAT). Volume III discusses the micro- and macro-economic viability of biogas sanitation systems.

ISAT ; GTZ (1999): Biogas - Costs and Benefits and Biogas – Programme Implementation. (= Biogas Digest , 3 ). Information and Advisory Services on Appropriate Technology (ISAT) and German Agency for Technical Cooperation GmbH (GmbH) URL [Accessed: 26.05.2019]Biogas: GP Option for Community Development

This document contains a short review on biogas technology and an overview on the green productivity concept and community development. It also contains a detailed construction manual for fixed-dome biogas plant at the household level for the digestion of animal dung. An operation manual is also given and wide information on biogas appliances, such as cooking stoves and reuse of remaining compost from the digesters.

KOOTTATEP, S. OMPONT, M. HWA, T.J. (2004): Biogas: GP Option for Community Development. Asian Productivity Organization (APO) URL [Accessed: 05.06.2019]Biogas Sanitation Systems

This PDF-presentation gives a good introduction to biogas sanitation as a sustainable and ecological sanitation approach. Basic principles and main features are illustrated. Some design considerations are also addressed.

MANG, H. P. (2005): Biogas Sanitation Systems. (= Ecological sanitation course ). Beijing: Chinese Academy of Agricultural EngineeringBiogas Sanitation Systems. International Conference on Ecosan

PowerPoint compilation of Chinese Experience on Ecosan and Biogas.

MANG, H.P. JURGA, I.P. (2005): Biogas Sanitation Systems. International Conference on Ecosan. Beijing: Chinese Academy of Agricultural Engineering URL [Accessed: 12.08.2010]Biogas Technology for Poverty Reduction and Sustainable Development

PDF-presentation on biogas technology basics and its potential for sustainable energy supply in rural areas.

NEMA, P.P. (n.y): Biogas Technology for Poverty Reduction and Sustainable Development. In: International Seminar on Biogas Technology for Poverty Reduction and Sustainable Development: URL [Accessed: 05.08.2010]Installation of a Low Cost Polyethylene Bio-digester

Manual for understanding the construction and operation of a low cost polyethylene biogas digester for rural households (agricultural wastes) in Belize. The manual is easily understandable and is addressed to a large public (users, local engineers/masons or public agents).

ORTEGA, M.O. (2009): Installation of a Low Cost Polyethylene Bio-digester. Belize Alibudon Society, Inter-American Institute for Cooperation on Agriculture (IICA) and Ministry of Agriculture and Fisheries (Belize)Improved Biogas Unit for Developing Countries

This booklet reflects seven years of experience of the Biogas Extension Service (BES) of CAMARTEC (Centre for Agricultural Mechanization and Rural Technology) in Arusha/Tanzania, which was carried out in cooperation with the GTZ from 1983 to 1986. It is meant as a teaching aid in agricultural colleges and as a reference book for professionals working in the field of rural biogas extension.

SASSE, L. (1991): Improved Biogas Unit for Developing Countries. German Appropriate Technology Exchange (GATE) and German Agency for Technical Cooperation (GTZ) GmbH URL [Accessed: 05.06.2019]Biogas Plants

This rather old document still gives a good overview on biogas technology. It is intended to help designers of a biogas plant to be able to distinguish between valid and invalid solutions.

SASSE, L. (1988): Biogas Plants. German Appropriate Technology Exchange (GATE) and German Agency for Technical Cooperation (GTZ) GmbH URL [Accessed: 15.05.2012]Training Material on Anaerobic Wastewater Treatment

This training manual emphasizes basics of biogas technology as well as design principles and technical considerations. A sample design exercise and some technical drawings and sketches are also given.

WAFLER, M. (2008): Training Material on Anaerobic Wastewater Treatment. (= Ecosan Expert Training Course ). Aarau: Seecon GmbH URLBiogas Plants in Animal Husbandry

This guide addresses the planners and providers of stock-farming and agricultural-extension services in developing countries. It is intended to serve as a source of information on the potentials of and prerequisites for biogas technology: a decision-making and planning aid for the construction and dissemination of biogas plants: a book of reference for information on practical experience and detailed data.

WERNER, U. STOEHR, U. HEES., N. (1989): Biogas Plants in Animal Husbandry. German Appropriate Technology Exchange (GATE) and German Agency for Technical Cooperation (GTZ) GmbHAsia hits the gas

Biogas technology is already working extremely well on a large scale in several Asian countries. This article reports on some of these successes and recent up-scaling initiatives, and makes a plea for a global conference on biogas.

NES, W.J., van (2006): Asia hits the gas. In: Renewable Energy World: Volume 1 , 102-111. URL [Accessed: 24.04.2010]Biogas, Saving Nature Naturally

This article shows how biogas technology could improve the life of rural habitants in Nepal by preserving the nature.

GURUNG, T. (2007): Biogas, Saving Nature Naturally. In: EcoCircular: Volume 42 , 1-3. URL [Accessed: 25.04.2010]Smart Sanitation Solutions

Smart Sanitation Solutions presents examples of low-cost household and community-based sanitation solutions that have proven effective and affordable. A wide range of innovative technologies for toilets, collection, transportation, treatment and use of sanitation products that have already helped thousands of poor families to improve their lives is illustrated.

NWP (2006): Smart Sanitation Solutions. Examples of innovative, low-cost technologies for toilets, collection, transportation, treatment and use of sanitation products. (= Smart water solutions ). Amsterdam: Netherlands Water Partnership (NWP) URL [Accessed: 09.05.2019]Biogas Support Programme fuels rural household energy supply in Nepal

The widespread adoption of biogas technology in Nepal is due to its modular and easy to construct design, its proven reliability, the immediate noticeable benefits and the long term financial incentives provided by the government and international donors. The early involvement and active entrepreneurship of the private sector has been crucial to the success. Despite the economic, technical and social barriers discussed, the success of biogas support programme (BSP) evolves around institutional sustainability, technical sustainability and financial sustainability. And by introducing a strong quality management component to the programme, it helps to ensure that supply-side actors remain fully accountable to their customers.

SNV (2010): Biogas Support Programme fuels rural household energy supply in Nepal. Netherlands Development Organisation (SNV) URL [Accessed: 28.04.2010]Reuse of Energy (Biogas)

Using Human Waste

This Technical Brief introduces the main issues one needs to consider to both control the process and optimize the benefits gained from using human waste, whilst minimizing the risks.

WELL (n.y): Using Human Waste. (= WELL Technical Briefs , 63 ). Loughborough: Water and Environmental health at London and Loughborough (WELL) URL [Accessed: 26.04.2010]http://www.bspnepal.org.np/

The national biogas extension programme in Nepal has been carried out successfully by the biogas support partnership (BSP). Their homepage reflects and capitalizes their experience in small-scale anaerobic biogas digester dissemination and construction.

International Seminar on Biogas Technology for Poverty Reduction and Sustainable Development

This webpage presents the proceedings of the International Seminar on Biogas Technology for Poverty Reduction and Sustainable Development, jointly sponsored by the United Nations Economic and Social Commission for Asia and the Pacific (UNESCAP) and the Ministry of Agriculture of China (MOA) (18 to 20 October, 2005, Beijing). Utilisation of household biogas systems and large-scale biogas systems as a means to boost rural economy, while contributing to rural poverty reduction and sustainable development are discussed.

Netherlands Development Organisation (SNV) library

The Netherlands Development Organisation (SNV) library hosts an extensive choice of domestic biogas reports from around the world domestic biogas.

Various biogas sanitation photos

This Flickr slideshow shows different low-cost biogas plants from all over the world.

http://www.journeytoforever.org/biofuel_library/methane_nepal.html

Online construction manual of the 2047 design GGC model biogas plant (Nepalese biogas plant model).

Biogas processes for sustainable development

This review is intended to up-date students, practitioners and consultants concerned with Biogas technologies, and to contribute to bringing biogas systems to a more advanced stage, and thereby to achieve a palpable impact in developing countries. Technical, social, environmental ad economic issues are addressed.

http://www.youtube.com

This is an instructional video taking you through all the processes of the improved biogas plant construction in Kampala, Uganda.