Pre-treatment is the preliminary removal of wastewater or sludge constituents, such as oil, grease, and various solids (e.g., sand, fibres and trash). Built before a conveyance or treatment technology, pre-treatment units can retard the accumulation of solids and minimize subsequent blockages. They can also help to reduce abrasion of mechanical parts and extend the life of the sanitation infrastructure.

Oil, grease, sand and suspended solids can impair transport and/or treatment efficiency through clogging and wear. Therefore, prevention and early removal of these substances is crucial for the durability of a treatment system. Pre-treatment technologies use physical removal mechanisms, such as screening, flotation, settling and filtration.

Behavioural and technical source control measures at the household or building level can reduce pollution loads and keep pre-treatment requirements low. For example, solid waste and cooking oil should be collected separately and not disposed of in sanitation systems. Equipping sinks, showers and the like with appropriate screens, filters and water seals can prevent solids from entering the system. Sewer inspection chambers should always be closed with manhole covers to prevent extraneous material from entering the sewer.

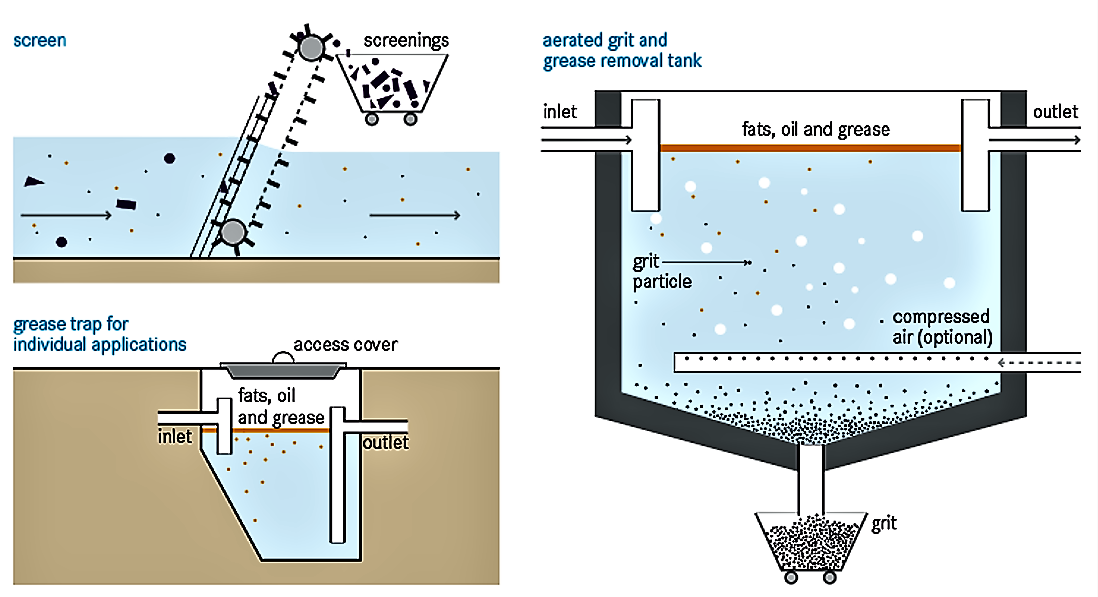

The goal of the grease trap is to trap oil and grease so that it can be easily collected and removed. Grease traps are chambers made out of brickwork, concrete or plastic, with an odour-tight cover. Baffles or tees at the inlet and outlet prevent turbulence at the water surface and separate floating components from the effluent. A grease trap can either be located directly under the sink, or, for larger amounts of oil and grease, a bigger grease interceptor can be installed outdoors. An under-the-sink grease trap is relatively low cost, but must be cleaned frequently (once a week to once a month), whereas a larger grease interceptor has a higher capital cost, but is designed to be pumped out every 6 to 12 months. If designed to be large enough, grease traps can also remove grit and other settleable solids through sedimentation, similar to septic tanks.

Screening aims to prevent coarse solids, such as plastics, rags and other trash, from entering a sewage system or treatment plant. Solids get trapped by inclined screens or bar racks. The spacing between the bars usually is 15 to 40 mm, depending on cleaning patterns. Screens can be cleaned by hand or mechanically raked. The latter allows for a more frequent solids removal and, correspondingly, a smaller design.

Where subsequent treatment technologies could be hindered or damaged by the presence of sand, grit chambers (or sand traps) allow for the removal of heavy inorganic fractions by settling. There are three general types of grit chambers: horizontal-flow, aerated, or vortex chambers. All of these designs allow heavy grit particles to settle out, while lighter, principally organic particles remain in suspension.

The removal of solids and grease from pre-treatment technologies is not pleasant and, if households or community members are responsible for doing this, it may not be done regularly. Hiring professionals to do the removal may be the best option though it is costly. The people involved in the cleaning may come in contact with pathogens or toxic substances; therefore, adequately protecting oneself with safety clothes, i.e., boots and gloves, is essential.

All pre-treatment facilities must be regularly monitored and cleaned to ensure proper functioning. If the maintenance frequency is too low, strong odours can result from the degradation of the accumulated material. Insufficiently maintained pre-treatment units can eventually lead to the failure of downstream elements of a sanitation system (see also operation and maintenance).

The pre-treatment products should be disposed of as solid waste in an environmentally sound way. In the case of grease, it may be used for energy production (e.g., biodiesel or co-digestion), or recycled for re-use.

Grease traps should be applied where considerable amounts of oil and grease are discharged. They can be installed at single households, restaurants or industrial sites. Grease removal is especially important where there is an immediate risk of clogging (e.g., a constructed wetland for the treatment of greywater).

Screening is essential where solid waste may enter a sewer system, as well as at the entrance of treatment plants. Trash traps, e.g., mesh boxes can also be applied at strategic locations like market drains.

As laundries release high amounts of fabric fibres and particles with their wastewater, they should be equipped with lint trap devices.

In the case where roads or not paved, rain water and/or storm water bring substantial amount of sand particles in the system. A Grit chamber helps to prevent the abrasion and sand deposition in the wastewater treatment plants.

Small and Decentralized Wastewater Management Systems

Decentralised wastewater management presents a comprehensive approach to the design of both conventional and innovative systems for the treatment and disposal of wastewater or the reuse of treaded effluent. Smaller treatment plants, which are the concern of most new engineers, are the primary focus of this book.

CRITES, R. TCHOBANOGLOUS, G. (1998): Small and Decentralized Wastewater Management Systems. New York: The McGraw-Hill Companies IncGreywater Management in Low and Middle-Income Countries, Review of Different Treatment Systems for Households or Neighbourhoods

This report compiles international experience in greywater management on household and neighbourhood level in low and middle-income countries. The documented systems, which vary significantly in terms of complexity, performance and costs, range from simple systems for single-house applications (e.g. local infiltration or garden irrigation) to rather complex treatment trains for neighbourhoods (e.g. series of vertical and horizontal-flow planted soil filters).

MOREL, A. DIENER, S. (2006): Greywater Management in Low and Middle-Income Countries, Review of Different Treatment Systems for Households or Neighbourhoods. (= SANDEC Report No. 14/06 ). Duebendorf: Swiss Federal Institute of Aquatic Science (EAWAG), Department of Water and Sanitation in Developing Countries (SANDEC) URL [Accessed: 27.05.2019]How to Design Wastewater Systems for Local Conditions in Developing Countries

This manual provides guidance in the design of wastewater systems in developing country settings. It promotes a context-specific approach to technology selection by guiding the user to select the most suitable technologies for their area. It provides tools and field guides for source characterization and site evaluation, as well as technology identification and selection. This manual is primarily addressed to private and public sector service providers, regulators and engineers/development specialists in charge of implementing wastewater systems.

ROBBINS, D.M. LIGON, G.C. (2014): How to Design Wastewater Systems for Local Conditions in Developing Countries. London: International Water Association (IWA) URL [Accessed: 20.01.2015]